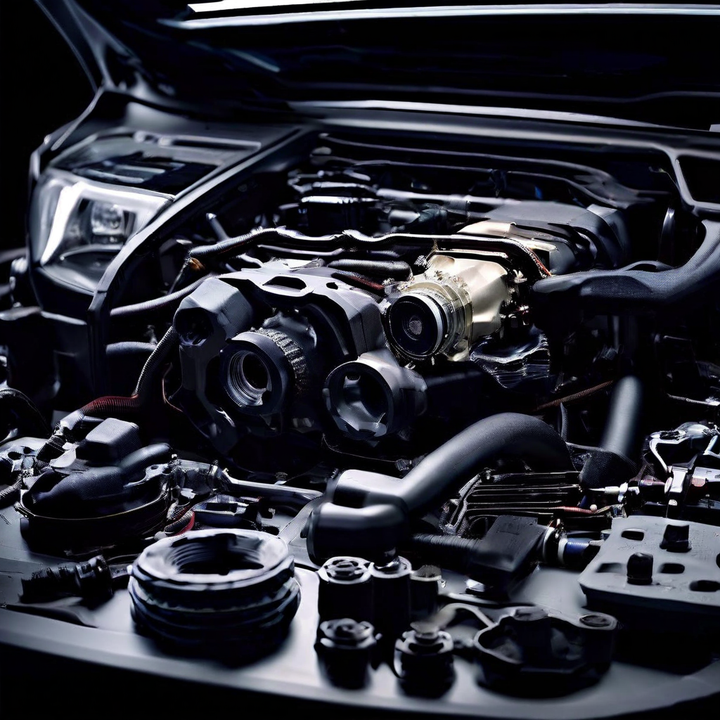

The 2.7L EcoBoost engine, introduced by Ford in 2015, has gained popularity for its impressive power and fuel efficiency. However, this turbocharged and direct-injected gasoline engine has also been subject to several common issues that prospective buyers and current owners should be aware of. This comprehensive guide delves into the most prevalent problems associated with the 2.7L EcoBoost, their causes, symptoms, and potential solutions. By understanding these issues, you can make informed decisions about maintenance, repairs, and ownership considerations.

The 2.7L EcoBoost engine is a compact and lightweight powerplant that combines turbocharging and direct injection technologies to deliver exceptional performance and fuel economy. With a displacement of 2.7 liters, this gasoline engine has found its way into various Ford and Lincoln vehicles, as shown in the following table:

| Vehicle Model | Engine Variant |

|---|---|

| Ford F-150 | 2.7L EcoBoost |

| Ford Bronco | 2.7L EcoBoost |

| Ford Edge | 2.7L EcoBoost |

| Lincoln Nautilus | 2.7L EcoBoost |

Despite its impressive capabilities, the 2.7L EcoBoost engine has been plagued by several common issues that can impact its performance, reliability, and longevity. Addressing these problems promptly is crucial to mitigate potential damage, prevent costly repairs, and ensure the engine's optimal operation.

Ignoring common issues with the 2.7L EcoBoost engine can lead to a range of performance-related problems and compromise the engine's overall reliability and durability. These issues can have significant cost implications, as neglecting to address them can result in more severe and costly repairs down the line.

One of the most frequently reported issues with the 2.7L EcoBoost engine is excessive carbon buildup on the intake valves. This problem can have a significant impact on the engine's performance and longevity if left unaddressed.

The direct injection system used in the EcoBoost engines is often cited as a contributing factor to carbon buildup on the intake valves. In this system, fuel is injected directly into the combustion chamber, which can lead to incomplete combustion and the accumulation of carbon deposits over time.

As carbon buildup on the intake valves increases, it can cause a range of symptoms, including:

Engine misfires

Hesitation during acceleration

Rough idling

Loss of power, particularly when the engine is under load

The direct injection system, while offering benefits in terms of fuel efficiency and power delivery, can exacerbate the issue of carbon buildup. The high-pressure injection process and the lack of fuel washing over the intake valves contribute to the accumulation of carbon deposits over time.

Another common problem reported by owners of the 2.7L EcoBoost engine is related to cam phaser issues, particularly in older trucks with higher mileage.

While cam phaser issues can occur in any vehicle equipped with the 2.7L EcoBoost engine, they seem to be more prevalent in older trucks with higher mileage. This could be due to wear and tear on the components over time or other factors related to the engine's age and usage.

Cam phaser issues can manifest in various symptoms, with rough idling being one of the most commonly reported. Additionally, owners may experience performance-related issues, such as hesitation or loss of power, particularly during acceleration or when the engine is under load.

Cam phaser issues can arise due to various factors, including:

Wear and tear

Oil sludge buildup

Faulty components

In some cases, replacing the cam phasers or addressing underlying issues, such as oil sludge buildup, may resolve the problem. However, in severe cases, more extensive repairs or even engine replacement may be necessary.

Head gasket failures are another concerning issue that has been reported by some owners of the 2.7L EcoBoost engine. These failures can have severe consequences and can be costly to repair.

Head gasket failures in the 2.7L EcoBoost engine can be attributed to various factors, including:

Manufacturing defects

Excessive heat or pressure

Improper maintenance

Overheating

Coolant leaks or other cooling system issues

When a head gasket fails, it can lead to a range of symptoms, such as:

Coolant leaks

Overheating

White smoke from the exhaust

Loss of power

If left unaddressed, a blown head gasket can cause further damage to the engine, potentially leading to costly repairs or even engine replacement.

Repairing a blown head gasket on the 2.7L EcoBoost engine can be a significant expense, often costing thousands of dollars in parts and labor. In some cases, the repair costs may exceed a substantial portion of the vehicle's value, making it a financially prudent decision to consider replacing the engine or even the vehicle itself.

A recent revelation has shed light on a potential design flaw in the oil pan used in the Bronco's version of the 2.7L EcoBoost engine. This issue has raised concerns among owners and prospective buyers.

The design flaw in question involves the positioning of the oil pickup tube within the oil pan. In certain situations, such as during aggressive off-road driving or sudden changes in terrain, the oil level can shift, causing the pickup tube to become uncovered.

When the oil pickup tube becomes uncovered, it can lead to air being sucked into the engine, potentially causing significant damage to various components, including:

Valves

Bearings

Other internal engine parts

This issue can result in costly repairs or even engine failure if left unaddressed.

To mitigate the risks associated with this design flaw, Ford has recommended several preventive measures, such as avoiding aggressive off-road driving or sudden changes in terrain. Additionally, some owners have opted for aftermarket solutions, such as installing an extended oil pickup tube or modifying the oil pan design.

While the 2.7L EcoBoost engine offers impressive performance and fuel efficiency, its reliability and longevity have been the subject of ongoing discussions and debates among owners and automotive experts.

Despite its advanced engineering and cutting-edge technology, the 2.7L EcoBoost engine has raised concerns regarding its long-term reliability. The common issues discussed in this guide, such as carbon buildup, cam phaser problems, head gasket failures, and the oil pan design flaw, have contributed to these concerns.

However, it's important to note that many owners have reported high-mileage examples of the 2.7L EcoBoost engine holding up well with proper maintenance. Regular oil changes, using high-quality oil, and addressing any issues promptly can significantly improve the engine's longevity and mitigate potential problems.

The table below shows some examples of high-mileage 2.7L EcoBoost engines reported by owners:

| Vehicle Model | Mileage | Maintenance Practices |

|---|---|---|

| Ford F-150 | 150,000 miles | Regular oil changes, high-quality oil |

| Ford Bronco | 120,000 miles | Addressed issues promptly |

| Ford Edge | 180,000 miles | Followed recommended service intervals |

When compared to other Ford engines, such as the 5.0L V8, the 2.7L EcoBoost may offer better fuel efficiency and power delivery, but its reliability remains a topic of debate. While some owners have had positive experiences with the 2.7L EcoBoost, others have encountered issues that have raised questions about its long-term durability.

The following table compares the key characteristics of the 2.7L EcoBoost and the 5.0L V8 engines:

| Engine | Fuel Efficiency | Power Delivery | Reported Reliability |

|---|---|---|---|

| 2.7L EcoBoost | Higher | Impressive | Mixed reviews |

| 5.0L V8 | Lower | Powerful | Generally reliable |

Proper maintenance and preventive measures are crucial for mitigating potential issues with the 2.7L EcoBoost engine and ensuring its optimal performance and longevity.

Regular oil changes are one of the most important maintenance practices for the 2.7L EcoBoost engine. Using high-quality oil and adhering to the recommended service intervals can help prevent excessive carbon buildup, sludge formation, and other issues that can lead to engine problems.

The table below shows the recommended oil change intervals for the 2.7L EcoBoost engine:

| Driving Conditions | Oil Change Interval |

|---|---|

| Normal Driving | Every 7,500 miles or 12 months |

| Severe Driving | Every 5,000 miles or 6 months |

Addressing any issues or warning signs promptly is essential to prevent further damage and costly repairs. If you notice symptoms such as engine misfires, rough idling, or loss of power, it's important to have the vehicle inspected by a qualified technician as soon as possible.

In some cases, preventive measures or modifications may be recommended to mitigate specific issues. For example, to address the oil pan design flaw in the Bronco's 2.7L EcoBoost engine, Ford has suggested avoiding aggressive off-road driving or sudden changes in terrain. Additionally, some owners have opted for aftermarket solutions, such as installing an extended oil pickup tube or modifying the oil pan design.

When faced with major issues related to the 2.7L EcoBoost engine, repair costs and financial considerations become a significant factor in the decision-making process.

Repairing major issues with the 2.7L EcoBoost engine can be expensive, with costs varying depending on the specific problem and the extent of the damage. The following table provides an estimate of repair costs for common issues:

| Repair | Estimated Cost |

|---|---|

| Carbon Buildup Cleaning | $500 - $1,000 |

| Cam Phaser Replacement | $1,000 - $2,500 |

| Head Gasket Replacement | $2,000 - $4,000 |

| Engine Replacement | $6,000 - $10,000 |

When considering repairs, it's essential to weigh the costs against the vehicle's overall value and the potential longevity of the repaired engine. In some cases, the repair costs may exceed a substantial portion of the vehicle's value, making it a financially prudent decision to consider replacing the vehicle altogether.

Additionally, it's crucial to consider the long-term costs associated with owning a vehicle with a potentially problematic engine. Even after a major repair, there may be lingering concerns about the engine's reliability and the possibility of future issues arising. In such cases, it may be more cost-effective to explore alternative options, such as trading in the vehicle or purchasing a different model with a proven track record of reliability.

The 2.7L EcoBoost engine, while offering impressive performance and fuel efficiency, has been subject to several common issues that prospective buyers and current owners should be aware of. From carbon buildup on intake valves to cam phaser problems, head gasket failures, and the oil pan design flaw, these issues can have a significant impact on the engine's performance, reliability, and longevity.

To mitigate these risks, it is crucial to prioritize proper maintenance, address any issues promptly, and carefully consider repair costs and long-term ownership implications. By being informed and proactive, owners can make informed decisions about maintaining their 2.7L EcoBoost engine or exploring alternative options.

Ultimately, while the 2.7L EcoBoost engine has its strengths, its potential issues should not be overlooked. By understanding the common problems, their causes, and potential solutions, you can make informed choices that align with your priorities and ensure a satisfactory ownership experience.

The direct injection system in the 2.7L EcoBoost engine sprays fuel directly into the combustion chamber for more efficient combustion and improved fuel economy. It eliminates the need for fuel washing over the intake valves, which can lead to carbon buildup.

Common symptoms of cam phaser issues include rough idling and performance-related problems like hesitation or loss of power, particularly during acceleration or when the engine is under load.

Head gasket failures can be identified by symptoms such as coolant leaks, overheating, white smoke from the exhaust, and loss of power.

The oil pan design flaw can lead to the oil pickup tube becoming uncovered during aggressive off-road driving or sudden changes in terrain, potentially causing air to be sucked into the engine and damaging various components.

For normal driving conditions, Ford recommends changing the oil in the 2.7L EcoBoost engine every 7,500 miles or 12 months. For severe driving conditions, the interval is reduced to every 5,000 miles or 6 months.

The CGI block used in the 2.7L EcoBoost engine is extremely durable and lightweight, offering better vibration dampening properties than aluminum while being almost double the tensile strength of cast iron.

The 2.7L EcoBoost engine offers higher fuel efficiency but lower power delivery compared to the 5.0L V8. However, it provides impressive power for its size and displacement.

The twin-turbocharger design in the 2.7L EcoBoost engine helps recycle exhaust gases to pressurize the air entering the combustion chamber, resulting in greater power output and reduced turbo lag compared to single-turbocharger designs.

The offset I-beam connecting rods in the 2.7L EcoBoost engine provide a better mechanical advantage for transferring power to the crankshaft, resulting in improved efficiency and fuel savings.

Ignoring common issues with the 2.7L EcoBoost engine can lead to performance-related problems, compromise the engine's reliability and durability, and result in more severe and costly repairs down the line.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.