Diesel engines are widely used in various applications, including trucks, buses, construction equipment, and marine vessels, due to their durability, fuel efficiency, and high torque output. However, like any mechanical system, diesel engines can experience starting issues, which can be frustrating and potentially costly if not addressed promptly. Understanding the common causes and troubleshooting techniques for diesel engine starting problems is crucial for maintaining reliable operation and preventing further damage.

Before we dive into the troubleshooting process, it's essential to understand the primary reasons why a diesel engine might not start. Here are the most common culprits:

| Cause | Description |

|---|---|

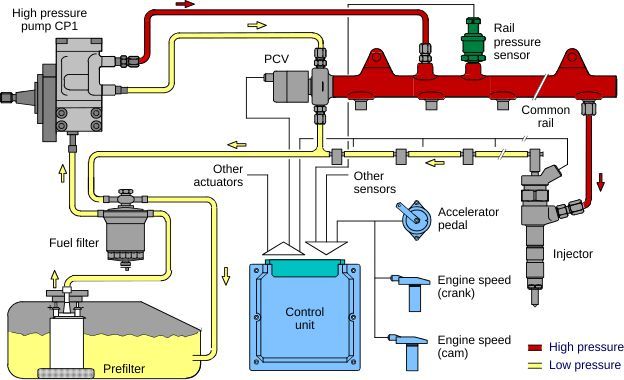

| Fuel System Issues | Clogged fuel filters, faulty fuel pumps, leaks in fuel lines, contaminated fuel |

| Electrical System Problems | Dead battery, faulty starter motor, wiring issues |

| Compression Issues | Worn piston rings, valve problems, blown head gasket |

| Glow Plug System Failure | Faulty glow plugs or glow plug relay in cold weather |

When faced with a diesel engine that won't start, it's essential to follow a systematic troubleshooting approach to identify the root cause. Here are the steps I typically take:

Check Battery Voltage and Connections

Inspect the Fuel System

Check Glow Plug Operation

Perform a Compression Test

Check Starter Motor Operation and Wiring

Scan for Diagnostic Trouble Codes

Once the root cause of the issue has been identified, it's time to address the necessary repairs. Here are some common repair instructions I follow:

| Repair | Description |

|---|---|

| Fuel System Repairs | Replace clogged filters, damaged fuel lines, faulty fuel pump. Bleed air from fuel system. |

| Electrical System Repairs | Replace dead battery, faulty starter motor, damaged wiring, and relays. |

| Compression Repairs | Repair or replace worn piston rings, valves, head gasket, etc. |

| Glow Plug System Repairs | Replace faulty glow plugs and relay. Ensure proper operation. |

While repairs are sometimes necessary, taking preventive measures can help avoid many issues that cause a diesel engine to fail to start. Here are some recommendations I provide to my customers:

Regular maintenance: Change fuel filters, air filters, and engine oil as per schedule.

Fuel quality: Use high-quality diesel fuel and fuel additives to prevent contamination.

Battery maintenance: Check battery condition, clean terminals, and replace if needed.

Proper operation: Avoid excessive idling, follow manufacturer's guidelines.

The cost of repairing a diesel engine that won't start can vary widely depending on the underlying issue. Here are some common cost estimates:

| Repair | Cost Range |

|---|---|

| Fuel system repairs | $200 - $1,000 |

| Electrical system repairs | $300 - $1,500 |

| Compression repairs | $1,500 - $5,000 |

| Glow plug system repairs | $100 - $500 |

| Diagnostic costs | $100 - $300 |

It's essential to address the issue promptly to prevent further damage and potential safety hazards. Consulting with a qualified diesel mechanic is recommended for accurate diagnosis and cost estimates.

Dealing with a diesel engine that won't start can be frustrating, but with the right knowledge and approach, the issue can be resolved. As a diesel mechanic, I've encountered numerous cases where a systematic troubleshooting process, combined with proper repairs and preventive measures, has helped get diesel engines back on the road.

Remember, addressing the root cause is crucial, whether it's a fuel system problem, electrical issue, compression leak, or glow plug system failure. Regular maintenance and following proper operating procedures can also go a long way in preventing many starting issues from occurring in the first place.

If you find yourself in a situation where your diesel engine won't start, don't hesitate to seek professional assistance. A qualified mechanic can accurately diagnose the problem and provide the necessary repairs to get you back on the road safely and efficiently.

Check the battery voltage and connections first, as a dead or disconnected battery is a common cause of starting issues.

Inspect the fuel filters, fuel lines, and fuel pump for any clogs, leaks, or damage, and ensure the fuel quality is good.

Glow plugs are used to preheat the combustion chambers in cold weather to aid in starting the engine.

A compression test involves using a specialized gauge to measure the compression in each cylinder, indicating potential issues with piston rings, valves, or head gaskets.

The starter motor is responsible for cranking the engine during the starting process, and a faulty starter motor can prevent the engine from turning over.

Yes, a malfunctioning ECM or other electronic components can prevent the engine from starting, as they control various systems essential for the starting process.

Colder temperatures can make it more difficult to start a diesel engine, as the engine oil thickens, and additional preheating may be required.

Diagnostic scan tools, multimeters, and compression testers are commonly used to diagnose starting issues in diesel engines.

Proper maintenance records can help identify patterns, track repairs, and ensure compliance with manufacturer recommendations, which can aid in troubleshooting and preventing future issues.

Yes, using low-quality or contaminated fuel can lead to clogged filters, fuel system issues, and potentially prevent the engine from starting.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.