Friction is an inherent force that opposes the relative motion between surfaces in contact, leading to energy losses and accelerated wear. In the automotive industry, minimizing friction is crucial for improving fuel efficiency, extending component life, and reducing maintenance costs. This is where friction reduction additives come into play, offering innovative solutions to enhance the performance and durability of automotive systems.

This comprehensive article delves into the world of friction reduction additives, exploring their types, working mechanisms, applications, and the latest advancements in this field. We will uncover the science behind these specialized compounds and their role in optimizing automotive lubrication, ultimately contributing to a more sustainable and efficient driving experience.

Friction reduction additives encompass a diverse range of chemical compounds, each with unique properties and mechanisms of action. Understanding their characteristics is essential for selecting the appropriate additive for specific automotive applications.

Here are the main types of friction reduction additives:

| Additive Type | Description |

|---|---|

| Organic Friction Modifiers (OFMs) | Amphiphilic molecules that form protective films on metal surfaces, with a polar head group adsorbing onto the metal and a lipophilic hydrocarbon tail aligning outward into the lubricating oil, creating a low-friction surface. Examples include glycerol monooleate and fatty acid esters. |

| Organomolybdenum Friction Modifiers (MFMs) | Additives that form nano-sized sheets dispersed in a carbon or pyrite matrix, which orient themselves in layers and slide against each other, reducing friction. Molybdenum dithiocarbamate (MoDTC) is a prominent example. |

| Polymer-based Friction Modifiers | Functionalised polymers, such as polyalkylene glycols (PAGs), that exhibit a strong affinity for metal surfaces due to their polarity, forming durable, low-friction lubricating films. |

| Hybrid Friction Modifiers | Developed by CIDETEC, these additives combine lamellar chalcogenide nanoparticles (e.g., MoS2, WS2) with organic moieties, resulting in a unique combination that significantly improves tribological performance. |

Organic friction modifiers (OFMs) are amphiphilic molecules that form protective films on metal surfaces. These additives possess a polar head group that adsorbs onto the metal surface and a lipophilic hydrocarbon tail that aligns outward into the lubricating oil. This unique molecular structure creates a low-friction surface, reducing the direct metal-to-metal contact and minimizing wear.

Examples of OFMs include glycerol monooleate and fatty acid esters. These compounds are widely used in engine oils, transmission fluids, and other automotive lubricants due to their ability to improve fuel economy and extend component life.

Organomolybdenum friction modifiers (MFMs) are a class of additives that form nano-sized sheets dispersed in a carbon or pyrite matrix. These sheets orient themselves in layers, allowing them to slide against each other and effectively reduce friction. Molybdenum dithiocarbamate (MoDTC) is a prominent example of an MFM, commonly used in automotive lubricants.

MFMs are particularly effective in boundary lubrication conditions, where the lubricant film is thin or non-existent, making them valuable for applications such as engine components and transmission gears.

Polymer-based friction modifiers are functionalised polymers that exhibit a strong affinity for metal surfaces due to their polarity. These additives form durable, low-friction lubricating films on metal surfaces, providing excellent wear protection and friction reduction.

Polyalkylene glycols (PAGs) are a widely used class of polymer-based friction modifiers in automotive lubricants. Their ability to form stable films and their compatibility with various lubricant formulations make them versatile additives for a range of automotive applications.

Hybrid friction modifiers represent a cutting-edge development in the field of friction reduction additives. Developed by CIDETEC, these additives combine lamellar chalcogenide nanoparticles, such as molybdenum disulfide (MoS2) or tungsten disulfide (WS2), with organic moieties.

This unique combination results in a synergistic effect, significantly improving the tribological performance of lubricants and composite materials. Hybrid friction modifiers offer superior friction reduction capabilities and enhanced wear protection, making them ideal for high-performance automotive applications.

The effectiveness of friction reduction additives lies in their ability to form protective films or layers on metal surfaces, reducing direct metal-to-metal contact and providing a low-shear interface. However, the specific mechanisms vary depending on the additive type.

Organic friction modifiers (OFMs) and polymer-based friction modifiers work by forming dense monolayers or thick, reacted viscous layers on metal surfaces. In the case of OFMs, the hydrocarbon tails align vertically, creating a low-friction surface. Polymer-based additives, on the other hand, form durable, low-friction lubricating films due to their polarity and affinity for metal surfaces.

Organomolybdenum friction modifiers (MFMs) and hybrid friction modifiers rely on the formation of layered nanostructures. MFMs form nano-sized sheets that orient themselves in layers, allowing them to slide against each other and reduce friction. Hybrid friction modifiers combine lamellar chalcogenide nanoparticles with organic moieties, resulting in a unique combination that enhances their tribological performance.

In addition to physical mechanisms, some friction reduction additives undergo tribochemical reactions on the metal surface, contributing to their effectiveness. For example, organomolybdenum compounds can undergo chemical reactions, forming molybdenum disulfide (MoS2) sheets that provide excellent lubricity and wear protection.

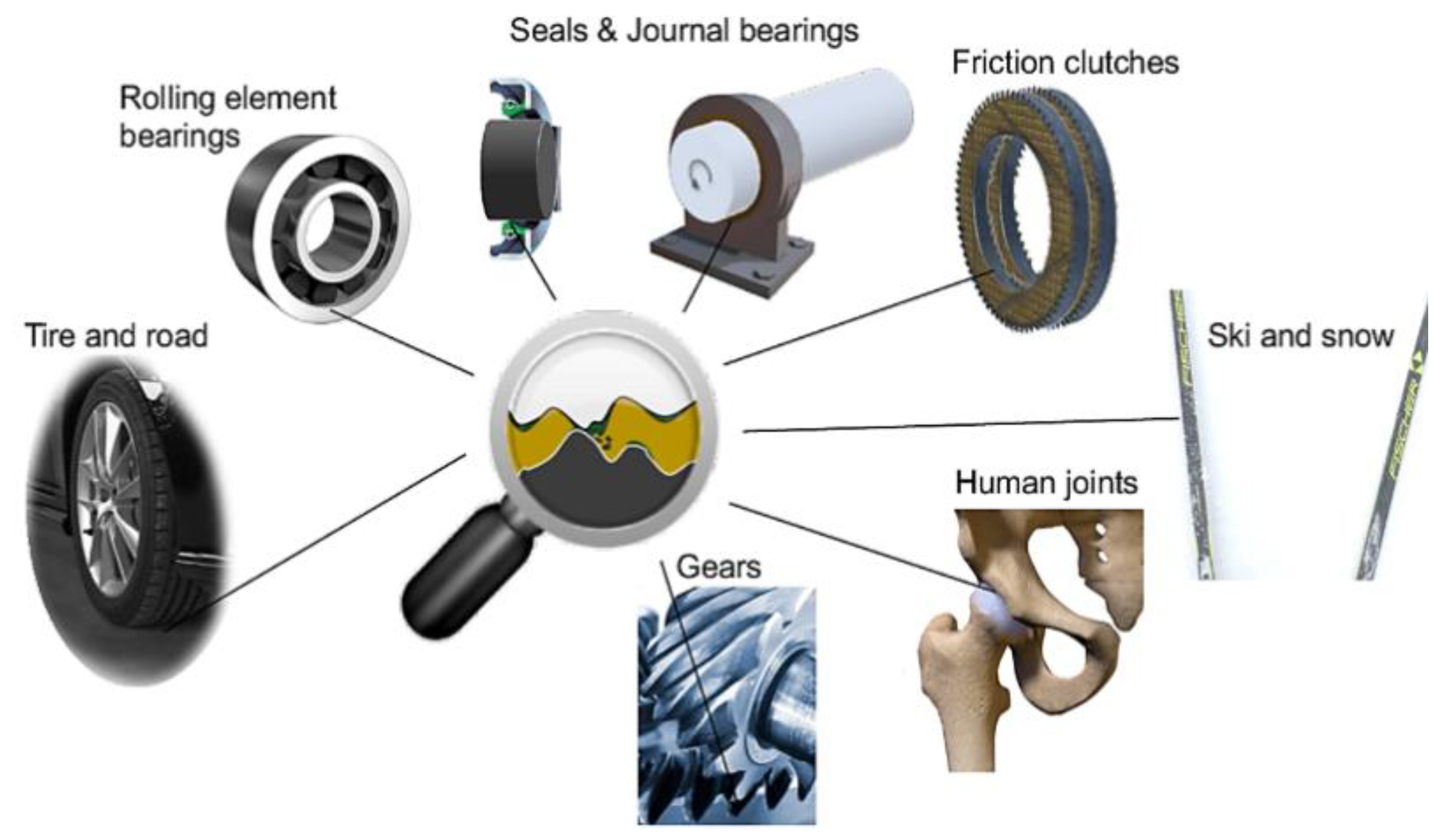

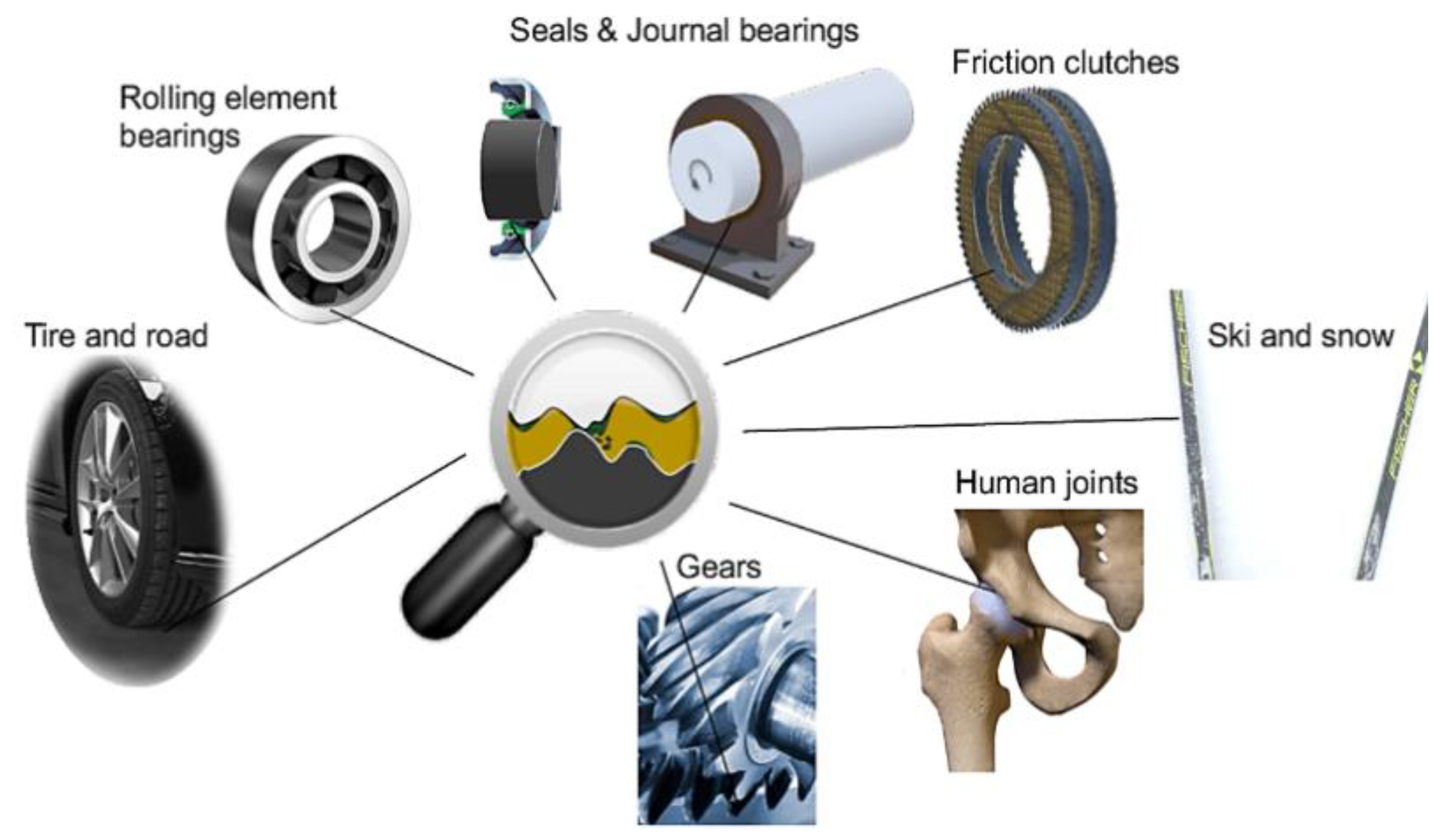

Friction reduction additives find widespread applications in various automotive systems, contributing to improved fuel efficiency, reduced wear, and extended component life.

Engine Oils: Formulated with friction reduction additives to minimize friction between moving parts, such as pistons, bearings, and valvetrain components, improving fuel economy, reducing emissions, and extending engine life.

Transmission Fluids: Automatic and manual transmission fluids benefit from these additives, reducing friction between gears, clutches, and other components, improving shifting performance and extending transmission lifespan.

Gear Oils: Used in differentials, transfer cases, and other automotive gearboxes, these additives minimize gear wear, reduce power losses, and improve overall efficiency, contributing to better fuel economy and longer component life.

Greases and Chassis Lubricants: Essential for lubricating suspension components, wheel bearings, and other automotive components subjected to high loads and extreme conditions, these additives help reduce friction, minimize wear, and extend service life.

The effectiveness of friction reduction additives in improving fuel economy and reducing wear has been well-documented through extensive research and testing.

Studies have shown that organic friction modifiers and organomolybdenum additives can provide fuel economy improvements ranging from a few tenths of a percent to over 1% in standardized engine tests. These improvements may seem small, but they can translate into significant savings over the lifetime of a vehicle, especially for commercial fleets and heavy-duty vehicles.

CIDETEC's hybrid friction modifiers have demonstrated remarkable performance, achieving over 50% reduction in friction coefficient compared to commercial oils without these advanced additives. This substantial reduction in friction can lead to significant energy savings and extended component life in various automotive applications.

| Additive Type | Fuel Economy Improvement | Friction Coefficient Reduction |

|---|---|---|

| Organic Friction Modifiers | Up to 1% | - |

| Organomolybdenum Friction Modifiers | Up to 1% | - |

| Hybrid Friction Modifiers | - | Over 50% |

It is important to note that the performance of friction reduction additives can be influenced by various factors, such as:

Lubricant formulation

Engine design

Operating conditions

Interactions with other additives in the lubricant package

Careful selection and compatibility testing are crucial to ensure optimal performance and avoid any adverse effects.

While friction reduction additives offer significant benefits, it is essential to consider their potential environmental and safety implications.

Some additives, such as organomolybdenum compounds, may raise concerns regarding toxicity and environmental impact. Manufacturers and users should follow appropriate handling and disposal guidelines to mitigate any risks and ensure compliance with environmental regulations.

Certain friction reduction additives may pose health and safety risks if not handled properly. Appropriate personal protective equipment (PPE) and safe handling practices should be implemented to minimize exposure risks during manufacturing, transportation, and use.

The development of friction reduction additives is an active area of research, with ongoing efforts to improve their performance, reduce environmental impact, and explore new applications.

Emerging technologies, such as CIDETEC's hybrid friction modifiers, demonstrate the potential for innovative solutions that combine the advantages of different additive types. These advanced additives offer superior tribological performance while addressing environmental concerns and meeting the demanding requirements of modern automotive systems.

Research is underway to develop friction reduction additives specifically tailored for elastohydrodynamic lubrication conditions, which are prevalent in applications like bearings and gears. These tailored solutions could further enhance energy efficiency and component life in critical automotive systems.

As environmental concerns continue to gain prominence, the development of environmentally friendly and sustainable friction reduction additives is a priority. Researchers are exploring bio-based and biodegradable alternatives, as well as additives with reduced toxicity and improved eco-friendliness.

Friction reduction additives play a vital role in improving the performance and efficiency of automotive systems. By reducing friction between moving surfaces, these specialized compounds contribute to improved fuel economy, extended component life, and reduced energy consumption.

As the automotive industry continues to evolve, with a focus on sustainability and efficiency, the importance of friction reduction additives will only increase. Through ongoing research and development, these additives are poised to offer innovative solutions that address environmental concerns while delivering superior tribological performance across diverse automotive applications.

The main types are organic friction modifiers (OFMs), organomolybdenum friction modifiers (MFMs), polymer-based friction modifiers, and hybrid friction modifiers.

OFMs are amphiphilic molecules that form protective low-friction films on metal surfaces by adsorbing the polar head group onto the metal and aligning the hydrocarbon tail outwards.

MFMs react to form nano-sized sheets dispersed in a matrix, which orient themselves in layers and slide against each other, reducing friction.

Functionalised polymers like polyalkylene glycols exhibit strong affinity for metal surfaces due to their polarity, forming durable low-friction lubricating films.

Hybrid friction modifiers combine lamellar chalcogenide nanoparticles (e.g., MoS2, WS2) with organic moieties, resulting in superior tribological performance.

They are used in engine oils, transmission fluids, gear oils, greases, and chassis lubricants to improve fuel efficiency, reduce wear, and extend component life.

Studies show organic and organomolybdenum additives can provide fuel economy improvements ranging from a few tenths of a percent to over 1%.

Some additives may raise toxicity and environmental impact concerns, requiring proper handling and disposal. Appropriate personal protective equipment should be used.

Emerging trends include hybrid friction modifiers, tailored solutions for specific lubrication conditions, and the development of environmentally friendly and sustainable bio-based alternatives.

By reducing friction and wear, these additives help extend the lifespan of engine components, contributing to overall engine durability and reliability.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.