Modular and distributed brake systems represent a significant advancement in vehicle safety technology. These innovative braking solutions offer numerous benefits over traditional centralized braking systems, including improved fault tolerance, enhanced performance, and increased flexibility in vehicle design. By adopting modular and distributed brake systems, the automotive industry is poised to revolutionize the way vehicles handle braking and ensure a safer driving experience for everyone on the road.

In this article, we will explore the key aspects of modular and distributed brake systems, including their definitions, advantages, and challenges. We will also delve into the role of decentralization, segmentation, and compartmentalization in enhancing brake system performance and reliability. Additionally, we will discuss future trends and developments in this field, as well as the perspectives of various stakeholders involved in the implementation of these advanced braking technologies.

The evolution of braking systems in vehicles has been driven by the need for increased safety, reliability, and performance. As vehicles become more complex and sophisticated, traditional centralized braking systems have begun to show their limitations. Modular and distributed brake systems have emerged as a promising solution to address these challenges and pave the way for the future of vehicle safety.

Modular brake systems allow for the optimization of braking components based on specific vehicle requirements, such as powertrain type and driver assistance features. By enabling a more flexible and adaptable braking system design, modular brakes contribute to improved overall vehicle performance and efficiency.

Distributed brake systems take the concept of modularity a step further by utilizing brake-by-wire technology. This approach eliminates the need for mechanical and hydraulic connections between the brake pedal and the individual wheel brakes, instead relying on electronic signals to control braking force. Distributed brakes offer faster response times, reduced complexity, and easier integration with advanced driver assistance systems (ADAS) and autonomous driving technologies.

Modular brake systems are characterized by their ability to combine key braking components in various configurations to suit specific vehicle applications. This flexibility allows manufacturers to optimize the braking system for different powertrain types, such as internal combustion engines, hybrid vehicles, and fully electric vehicles.

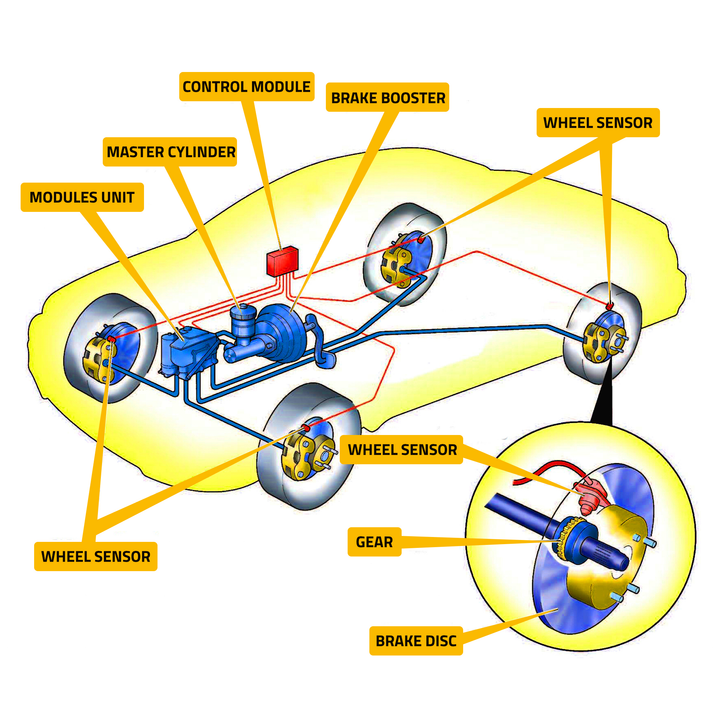

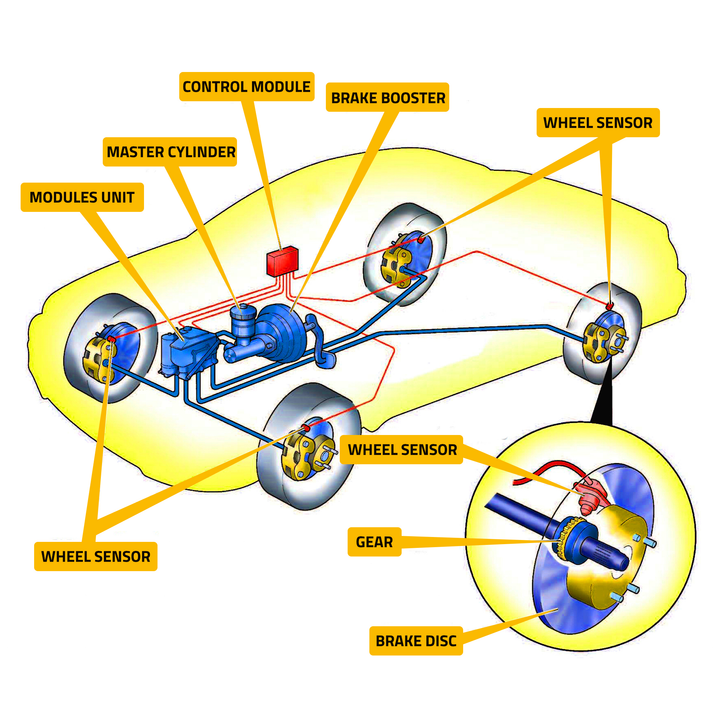

A modular brake system consists of interchangeable components that can be easily adapted to meet the unique requirements of a particular vehicle platform. These components typically include:

Brake boosters (vacuum or electromechanical)

Electronic stability control (ESC) modules

Brake calipers and rotors

Brake pads and sensors

By designing these components as modular units, manufacturers can mix and match them to create a customized braking system that best suits the vehicle's intended use and performance characteristics.

Modular brake systems offer several significant advantages over traditional centralized braking systems:

Optimization for different powertrain types: Modular brakes can be easily configured to work efficiently with various powertrain configurations, including internal combustion engines, hybrid powertrains, and all-electric systems. This adaptability ensures optimal braking performance regardless of the vehicle's propulsion method.

Energy recuperation in hybrid and electric vehicles: Modular brake systems can be designed to integrate seamlessly with regenerative braking systems in hybrid and electric vehicles. By capturing kinetic energy during braking and converting it into electrical energy, these systems help improve overall vehicle efficiency and extend the range of electric vehicles.

Support for driver assistance and automated driving functions: Modular brakes can be easily integrated with advanced driver assistance systems (ADAS) and autonomous driving technologies. By providing precise and responsive braking control, modular systems enable features such as automatic emergency braking, adaptive cruise control, and lane-keeping assist, enhancing overall vehicle safety.

Flexibility in component placement: The modular nature of these brake systems allows for greater flexibility in the placement of key components within the vehicle. This freedom in packaging enables manufacturers to optimize vehicle design for improved weight distribution, reduced complexity, and enhanced interior space utilization.

Modular brake systems can be configured in various ways to meet specific vehicle requirements. Some common configurations include:

| Configuration | Description |

|---|---|

| Vacuum booster + Standard ESC | Traditional vacuum brake booster paired with a standard electronic stability control module |

| Electromechanical booster + Standard ESC | Electromechanical brake booster combined with a standard ESC module for improved efficiency |

| Vacuum booster + Hybrid/EV-optimized ESC | Vacuum booster integrated with an ESC module specifically designed for hybrid and electric vehicles |

| Electromechanical booster + Hybrid/EV-optimized ESC | Electromechanical booster and a specialized ESC module optimized for regenerative braking in hybrid and electric vehicles |

These configurations demonstrate the versatility and adaptability of modular brake systems, allowing manufacturers to tailor the braking system to the unique needs of each vehicle platform.

Distributed brake systems represent a significant leap forward in braking technology, leveraging the power of brake-by-wire technology to provide even greater benefits than modular systems alone.

Brake-by-wire technology replaces the traditional mechanical and hydraulic connections between the brake pedal and the individual wheel brakes with electronic signals. When the driver presses the brake pedal, sensors detect the force applied and send electronic signals to the brake control module. This module then calculates the optimal braking force for each wheel and sends corresponding signals to the individual brake actuators.

By eliminating the need for physical connections, brake-by-wire systems offer several advantages, including faster response times, reduced weight, and improved packaging flexibility.

Distributed brake systems, which utilize brake-by-wire technology, offer a range of key features that set them apart from traditional braking systems:

Individual electronic control of each wheel's brakes: Distributed systems allow for precise control over the braking force applied to each wheel independently. This level of control enables advanced functions such as torque vectoring, which can enhance vehicle stability and handling in various driving conditions.

Elimination of brake fluid and reduced maintenance: By replacing hydraulic connections with electronic signals, distributed brake systems eliminate the need for brake fluid. This change reduces the overall weight of the braking system and minimizes maintenance requirements associated with hydraulic components, such as fluid leaks and regular fluid changes.

Advanced functions like automatic emergency braking and stability control: Distributed brake systems can easily integrate with advanced driver assistance systems (ADAS) to enable features such as automatic emergency braking and enhanced stability control. The rapid response times and precise control offered by brake-by-wire technology make these systems more effective and reliable.

Fault-tolerant operation through redundant electronic architecture: Distributed brake systems incorporate redundant electronic components and communication channels to ensure fail-safe operation. If one part of the system fails, the redundant components can take over, maintaining braking functionality and ensuring vehicle safety.

Faster response times compared to hydraulic systems: Electronic signals travel much faster than hydraulic pressure, allowing distributed brake systems to respond more quickly to driver inputs and changing road conditions. This improved responsiveness can be crucial in emergency braking situations, potentially reducing stopping distances and preventing accidents.

Integration with regenerative braking in hybrid and electric vehicles: Distributed brake systems can seamlessly integrate with regenerative braking systems in hybrid and electric vehicles. By precisely blending friction braking with regenerative braking, these systems optimize energy recovery and ensure smooth, consistent brake pedal feel for the driver.

Distributed brake systems offer numerous benefits over traditional hydraulic brakes, including:

Improved safety through faster response times and advanced functions

Reduced complexity and weight by eliminating hydraulic components

Enhanced vehicle stability and handling with individual wheel brake control

Easier integration with ADAS and autonomous driving technologies

Improved energy efficiency in hybrid and electric vehicles through regenerative braking integration

These benefits make distributed brake systems an attractive option for manufacturers looking to improve vehicle safety, performance, and efficiency.

Decentralization, segmentation, and compartmentalization are key concepts in the design of modular and distributed brake systems. These principles contribute to improved brake system performance, reliability, and maintainability.

Decentralization: By distributing braking functions across multiple modules and components, decentralization reduces the reliance on a single, centralized control unit. This approach improves overall system reliability and fault tolerance, as a failure in one module does not necessarily compromise the entire braking system.

Segmentation: Segmenting the braking system into smaller, more manageable units allows for easier troubleshooting and maintenance. If a problem arises, technicians can quickly identify and replace the affected module, minimizing downtime and repair costs.

Compartmentalization: Compartmentalizing brake system components helps to isolate potential faults and prevent them from propagating throughout the entire system. By containing issues within specific modules or circuits, compartmentalization enhances overall system stability and reliability.

Decentralization, segmentation, and compartmentalization play a crucial role in improving fault isolation and reducing single points of failure in brake systems:

By distributing braking functions across multiple modules, a failure in one module does not necessarily lead to a complete loss of braking capability.

Segmentation allows for easier identification and replacement of faulty components, minimizing the impact of failures on the overall system.

Compartmentalization helps to prevent the propagation of faults, ensuring that issues remain isolated within specific modules or circuits.

These concepts work together to create a more resilient and fault-tolerant braking system, ultimately enhancing vehicle safety and reliability.

The implementation of decentralization, segmentation, and compartmentalization in modular and distributed brake systems leads to simplified troubleshooting and maintenance procedures:

Technicians can quickly identify and replace faulty modules or components, reducing diagnostic time and repair costs.

Modular design allows for easier access to individual components, streamlining maintenance tasks such as brake pad and rotor replacements.

Compartmentalization helps technicians isolate issues more effectively, enabling targeted repairs and minimizing the need for extensive system overhauls.

By simplifying troubleshooting and maintenance, these concepts contribute to reduced vehicle downtime, lower ownership costs, and improved overall customer satisfaction.

While modular and distributed brake systems offer numerous benefits, their implementation also presents certain challenges and considerations that manufacturers must address.

One of the primary challenges in implementing modular and distributed brake systems is ensuring adequate fail-safe mechanisms. As these systems rely heavily on electronic components and communication networks, it is crucial to incorporate redundant hardware and software to maintain braking functionality in the event of a failure.

Manufacturers must design fail-safe mechanisms that can detect and respond to potential faults, such as:

Redundant electronic control units (ECUs) that can take over in case of a primary ECU failure

Backup communication channels to ensure uninterrupted data transmission between modules

Fault-tolerant software algorithms that can adapt to changing conditions and maintain stable braking performance

By incorporating robust fail-safe mechanisms, manufacturers can ensure the safety and reliability of modular and distributed brake systems, even in the face of potential component failures.

Another significant challenge in implementing modular and distributed brake systems is ensuring compliance with existing safety standards and regulations. As these systems represent a departure from traditional braking technologies, they may require additional testing and validation to meet stringent safety requirements.

Manufacturers must work closely with regulatory bodies to demonstrate the safety and effectiveness of their modular and distributed brake systems. This process may involve:

Extensive testing and simulation to validate system performance under various operating conditions

Development of new testing protocols and standards specific to modular and distributed brakes

Collaboration with industry partners and government agencies to establish best practices and guidelines

By proactively addressing compliance issues and engaging with relevant stakeholders, manufacturers can ensure that their modular and distributed brake systems meet or exceed the necessary safety standards and regulations.

The adoption of modular and distributed brake systems can have a significant impact on overall vehicle design and packaging. As these systems offer greater flexibility in component placement, manufacturers must carefully consider how to optimize the integration of braking components within the vehicle architecture.

Some key considerations include:

Optimal placement of brake modules and components to minimize weight and maximize interior space

Integration with other vehicle systems, such as suspension, steering, and powertrain components

Accommodation of additional electronic components and wiring harnesses required for brake-by-wire systems

Ensuring adequate cooling and ventilation for electronic components to prevent overheating and ensure reliable operation

By carefully evaluating the impact of modular and distributed brake systems on vehicle design and packaging, manufacturers can create more efficient, space-saving, and user-friendly vehicle architectures that enhance overall customer satisfaction.

Finally, the successful implementation of modular and distributed brake systems depends on their adoption and acceptance by both vehicle manufacturers and consumers. Manufacturers must be willing to invest in the development and integration of these advanced braking technologies, recognizing the potential benefits they offer in terms of safety, performance, and efficiency.

Consumers, on the other hand, must be educated about the advantages of modular and distributed brake systems and feel confident in their reliability and effectiveness. This may require:

Clear communication and marketing efforts to highlight the benefits of these systems

Demonstration of the systems' safety and performance through real-world testing and customer testimonials

Collaboration with industry partners and media outlets to raise awareness and build trust in the technology

By actively promoting the adoption and acceptance of modular and distributed brake systems, manufacturers can help accelerate the transition towards safer, more advanced braking technologies in the automotive industry.

As the automotive industry continues to evolve, modular and distributed brake systems are poised to play an increasingly important role in shaping the future of vehicle safety and performance.

One of the key trends driving the development of modular and distributed brake systems is the growing adoption of vehicle electrification and autonomy. As more vehicles transition to hybrid and all-electric powertrains, the integration of advanced braking technologies becomes increasingly critical.

Modular and distributed brake systems offer several advantages in this context:

Seamless integration with regenerative braking systems to optimize energy recovery and extend electric vehicle range

Precise control over braking force at each wheel, enabling advanced stability and handling features

Faster response times and improved safety for autonomous driving systems, which rely on accurate and reliable braking performance

By leveraging the capabilities of modular and distributed brake systems, manufacturers can create vehicles that are not only safer but also more efficient and capable of supporting the demands of an increasingly electrified and autonomous future.

As research and development in modular and distributed brake systems continue, several potential advancements are on the horizon:

Wireless communication: The adoption of wireless communication protocols, such as 5G or dedicated short-range communications (DSRC), could enable faster and more reliable data transmission between brake system components, further improving response times and fault tolerance.

Advanced sensor technologies: The integration of advanced sensor technologies, such as radar, lidar, and high-resolution cameras, could provide brake systems with even more accurate and comprehensive data about the vehicle's surroundings, enabling more precise and proactive braking control.

Machine learning and artificial intelligence: The application of machine learning and artificial intelligence algorithms to brake system control could allow for more adaptive and personalized braking performance, tailoring the system's behavior to individual driving styles and preferences.

Lightweight materials: The use of advanced lightweight materials, such as carbon fiber composites or high-strength alloys, could help reduce the overall weight of brake system components, improving vehicle efficiency and performance.

By continually pushing the boundaries of modular and distributed brake system technology, manufacturers can create even safer, more efficient, and more capable vehicles that meet the evolving needs of the automotive industry.

As modular and distributed brake systems gain traction in the automotive industry, several real-world examples and case studies demonstrate their potential:

| Manufacturer | System | Description |

|---|---|---|

| Tesla | Brake-by-wire system | Tesla's electric vehicles feature a brake-by-wire system that seamlessly integrates regenerative braking with traditional friction braking, optimizing energy recovery and providing a smooth, consistent brake pedal feel. |

| Bosch | iBooster | Bosch's iBooster is an electromechanical brake booster that can be easily integrated into modular brake systems, providing improved efficiency and faster response times compared to traditional vacuum boosters. |

| Continental | MK C1 | Continental's MK C1 is a compact, integrated brake system that combines the brake actuation, brake booster, and control functions into a single module, reducing weight and complexity while improving performance. |

These examples showcase the potential of modular and distributed brake systems to revolutionize vehicle safety and performance, paving the way for a more advanced and efficient automotive future.

The successful implementation and adoption of modular and distributed brake systems require the collaboration and support of various stakeholders within the automotive industry.

Vehicle manufacturers play a crucial role in driving the adoption of modular and distributed brake systems. By investing in research and development, manufacturers can create innovative braking solutions that meet the evolving needs of the market. They must also work closely with suppliers and regulatory bodies to ensure that these systems meet the necessary safety standards and performance requirements.

Manufacturers can benefit from the adoption of modular and distributed brake systems in several ways:

Improved vehicle safety and performance, leading to increased customer satisfaction and brand loyalty

Reduced complexity and weight, resulting in lower production costs and improved fuel efficiency

Enhanced flexibility in vehicle design and packaging, enabling the creation of more space-efficient and user-friendly vehicle architectures

By embracing modular and distributed brake systems, vehicle manufacturers can position themselves at the forefront of automotive innovation and contribute to the development of safer, more efficient, and more advanced vehicles.

Suppliers of brake system components and technologies play a vital role in the development and implementation of modular and distributed brake systems. They must work closely with vehicle manufacturers to design and produce components that meet the specific requirements of each vehicle platform.

Suppliers can contribute to the advancement of modular and distributed brake systems by:

Investing in research and development to create innovative components and technologies that improve system performance and reliability

Collaborating with manufacturers to optimize the integration of brake system components into vehicle architectures

Ensuring the production of high-quality, cost-effective components that meet the necessary safety and performance standards

By actively engaging in the development of modular and distributed brake systems, suppliers can help drive the adoption of these advanced technologies and secure their position in an increasingly competitive automotive market.

Regulatory bodies, such as government agencies and industry associations, play a critical role in ensuring the safety and compliance of modular and distributed brake systems. They must establish and enforce standards and regulations that govern the design, testing, and performance of these systems.

Regulators can support the adoption of modular and distributed brake systems by:

Developing clear and comprehensive safety standards and testing protocols specific to these advanced braking technologies

Collaborating with manufacturers and suppliers to ensure that brake systems meet the necessary performance and safety requirements

Providing guidance and support to help manufacturers navigate the compliance process and bring their systems to market

By working closely with industry stakeholders and adapting regulations to accommodate the unique characteristics of modular and distributed brake systems, regulators can help facilitate the safe and effective deployment of these technologies in the automotive market.

Consumers are the ultimate beneficiaries of modular and distributed brake systems, as these technologies contribute to improved vehicle safety, performance, and efficiency. However, for these systems to be widely adopted, consumers must be educated about their benefits and feel confident in their reliability and effectiveness.

Manufacturers and industry stakeholders can help build consumer trust and acceptance of modular and distributed brake systems by:

Clearly communicating the advantages of these systems in terms of safety, performance, and convenience

Providing transparent information about the testing and validation processes used to ensure the reliability and effectiveness of these systems

Offering comprehensive warranty coverage and customer support to address any concerns or issues that may arise

By actively engaging with consumers and addressing their needs and concerns, the automotive industry can help accelerate the adoption of modular and distributed brake systems and contribute to a safer, more advanced driving experience for everyone on the road.

To better understand the advantages of modular and distributed brake systems, it is helpful to compare them with traditional centralized braking systems. The following table highlights the key differences between these braking technologies:

| Feature | Traditional Centralized Brakes | Modular Brake Systems | Distributed Brake Systems |

|---|---|---|---|

| Architecture | Centralized control unit and hydraulic connections | Interchangeable modules optimized for specific vehicle requirements | Brake-by-wire technology with electronic control of individual wheel brakes |

| Response Time | Slower due to hydraulic fluid pressure buildup | Faster than traditional systems due to optimized components | Fastest response times due to electronic signal transmission |

| Fault Tolerance | Limited redundancy and fault isolation | Improved fault tolerance through modular design and component redundancy | High fault tolerance with redundant electronic architecture and fail-safe mechanisms |

| Integration with ADAS | Difficult to integrate seamlessly | Easier integration due to modular design | Seamless integration with advanced driver assistance systems |

| Energy Efficiency | Limited energy recovery capabilities | Improved energy efficiency through integration with regenerative braking | Optimized energy recovery and blending of friction and regenerative braking |

| Maintenance | Regular fluid changes and component replacements | Simplified maintenance through modular component design | Reduced maintenance requirements by eliminating hydraulic components |

| Vehicle Design Flexibility | Constrained by centralized architecture | Increased flexibility in component placement and vehicle packaging | Maximum design flexibility with brake-by-wire technology |

This comparative analysis demonstrates the clear advantages of modular and distributed brake systems over traditional centralized brakes in terms of performance, safety, efficiency, and design flexibility. As the automotive industry continues to evolve, these advanced braking technologies will play an increasingly critical role in shaping the future of vehicle design and development.

Modular and distributed brake systems represent a significant step forward in the evolution of vehicle safety technology. By offering improved performance, reliability, and flexibility, these advanced braking systems are poised to revolutionize the way vehicles handle braking and contribute to a safer, more efficient driving experience for everyone on the road.

As the automotive industry continues to evolve, with a growing focus on electrification, autonomy, and connectivity, the adoption of modular and distributed brake systems will become increasingly critical. These technologies offer seamless integration with advanced driver assistance systems and regenerative braking, enabling vehicles to optimize energy recovery, reduce emissions, and provide more precise and responsive braking control.

However, the successful implementation and widespread adoption of modular and distributed brake systems will require close collaboration and support from all stakeholders within the automotive industry. Vehicle manufacturers, suppliers, regulators, and consumers must work together to address the challenges associated with these technologies, ensure compliance with safety standards, and promote the benefits of advanced braking systems.

As research and development continue to push the boundaries of what is possible with modular and distributed brake systems, we can expect to see even more innovative and capable solutions emerge in the coming years. By embracing these technologies and working to accelerate their adoption, the automotive industry can contribute to a future where vehicles are safer, more efficient, and more advanced than ever before.

The cost premium for vehicles with modular or distributed brake systems may vary depending on the specific implementation and vehicle segment. However, as these technologies become more widely adopted and economies of scale improve, the cost differential is expected to decrease over time.

Modular and distributed brake systems can contribute to reducing vehicle emissions and improving sustainability by enabling more efficient energy recovery through seamless integration with regenerative braking systems. By optimizing the blending of friction and regenerative braking, these technologies can help extend the range of electric vehicles and reduce overall energy consumption.

Technicians working on modular and distributed brake systems will need to have a strong understanding of electronic systems, communication networks, and diagnostic tools. They may require additional training in areas such as brake-by-wire technology, fault isolation, and software troubleshooting to effectively maintain and repair these advanced braking systems.

As with any system that relies on electronic components and communication networks, there is a potential for cybersecurity risks in modular and distributed brake systems. However, manufacturers are actively working to implement robust security measures, such as encryption, secure communication protocols, and intrusion detection systems, to mitigate these risks.

The widespread adoption of modular and distributed brake systems in the automotive industry is expected to occur gradually over the next decade. As more manufacturers invest in these technologies and consumer awareness and acceptance grow, we can expect to see an increasing number of vehicles equipped with these advanced braking systems in the coming years.

Modular and distributed brake systems are designed with advanced thermal management solutions to handle the increased heat generated during heavy braking. These solutions may include optimized brake pad and rotor materials, improved ventilation and cooling channels, and active thermal management systems that can dissipate heat more effectively.

In most cases, modular and distributed brake systems are designed to be integrated into new vehicle architectures from the ground up. While it may be technically possible to retrofit these systems to existing vehicles, it would likely require significant modifications to the vehicle's electrical and communication networks, making it a complex and costly endeavor.

Modular and distributed brake systems have the potential to reduce the overall weight of the vehicle compared to traditional braking systems. By eliminating the need for hydraulic components and utilizing lightweight materials in the construction of brake modules, these advanced braking technologies can contribute to improved vehicle efficiency and performance.

Government regulations and safety standards play a crucial role in the development and adoption of modular and distributed brake systems. Regulatory bodies are responsible for establishing and enforcing standards that ensure the safety and performance of these advanced braking technologies. Manufacturers must work closely with regulators to demonstrate compliance and bring their systems to market.

Modular and distributed brake systems are essential for the safe and effective operation of autonomous vehicles. By providing faster response times, precise control over individual wheel brakes, and seamless integration with advanced driver assistance systems, these technologies enable autonomous vehicles to make split-second decisions and execute complex maneuvers with a high degree of accuracy and reliability.

Miguel started tinkering with car radios as a teenager, fascinated by the intricate dance of wires and circuits. This passion led him to pursue a career as an automotive electrician. For the past 10 years, Miguel has tackled everything from flickering headlights to mysterious electrical gremlins. He thrives on troubleshooting electrical problems and enjoys sharing his knowledge to empower car owners to understand their vehicles better.