A cylinder misfire occurs when the combustion process within one of the engine's cylinders is incomplete or fails entirely. This can lead to a variety of performance issues, including rough idling, reduced power, and increased emissions. The P0311 code specifically indicates a misfire in cylinder 11, which can be caused by several factors.

| Cause Category | Specific Issues |

|---|---|

| Ignition System Problems | Faulty spark plugs or wires, Defective ignition coil, Malfunctioning distributor, cap, or rotor |

| Air-Fuel Mixture Issues | Vacuum leaks, Faulty fuel pump, Dirty or faulty fuel injectors, Failed fuel pressure regulator, Clogged fuel filter |

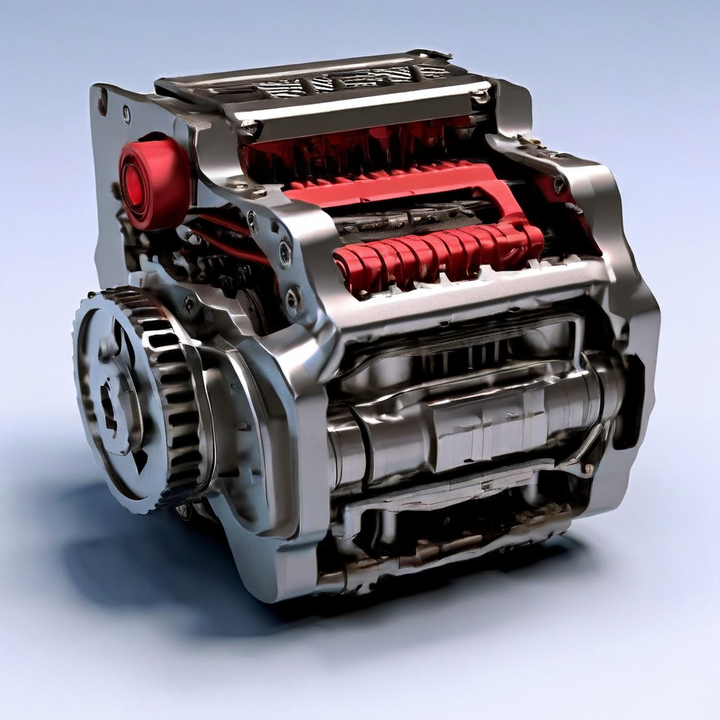

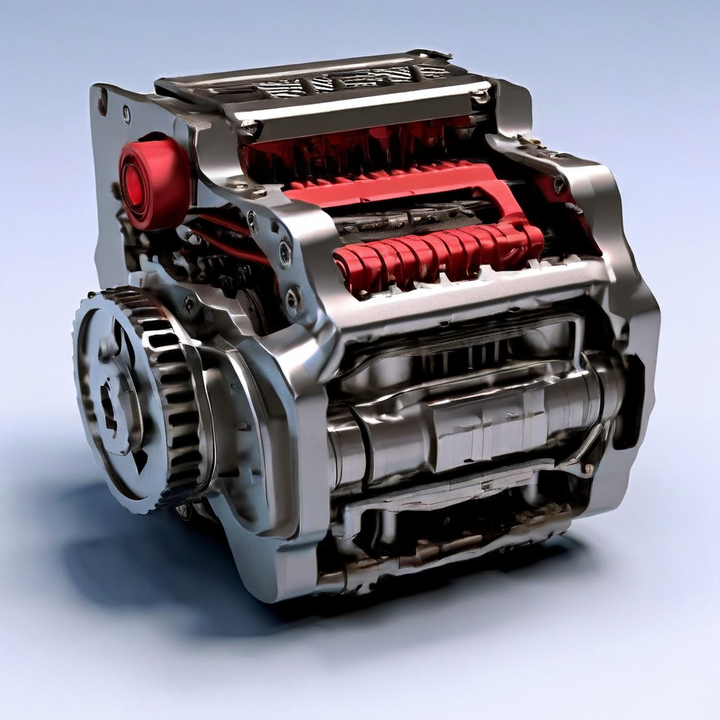

| Engine Mechanical Problems | Worn pistons, rings, or cylinder walls, Blown head gasket, Damaged valves or valvetrain components, Worn timing belt or chain |

| Sensor and Module Issues | Faulty mass airflow or crankshaft position sensor, PCM hardware or software failure, Circuit issues like damaged wires or poor connections |

| Other System Failures | Exhaust gas recirculation (EGR) system problems, Cylinder deactivation system issues, Variable valve timing system problems, Secondary air injection (SAI) system problems |

Ignition System Problems: Worn spark plugs can cause misfires by failing to ignite the air-fuel mixture properly.

Air-Fuel Mixture Issues: A faulty fuel injector can disrupt the balance of the air-fuel mixture, leading to misfires.

Engine Mechanical Problems: A blown head gasket can cause a loss of compression, resulting in a misfire.

Sensor and Module Issues: A bad crankshaft position sensor can send incorrect signals to the PCM, causing a misfire.

Other System Failures: EGR system problems can lead to improper exhaust gas recirculation, affecting combustion.

| Repair Category | Specific Actions |

|---|---|

| Ignition System Repairs | Replace faulty spark plugs, wires, or ignition coils. Inspect and replace the distributor cap or rotor if necessary. |

| Air-Fuel Mixture Repairs | Fix vacuum leaks. Replace or clean faulty fuel injectors. Replace the fuel pump or fuel pressure regulator if needed. Change the clogged fuel filter. |

| Engine Mechanical Repairs | Repair or replace worn pistons, rings, or cylinder walls. Replace the blown head gasket. Repair damaged valves or valvetrain components. Replace the worn timing belt or chain. |

| Sensor and Module Repairs | Replace faulty sensors (e.g., mass airflow or crankshaft position sensor). Repair or replace the PCM if it has a hardware or software failure. Fix damaged wires or poor connections. |

Regularly inspect and replace spark plugs and ignition components.

Perform routine checks on the fuel system, including the fuel pump, injectors, and filters.

Conduct periodic engine compression tests to identify mechanical issues early.

Regularly check and clean sensors to ensure they are functioning correctly.

Replacing Spark Plugs

Disconnect the battery.

Remove the ignition coil or spark plug wire.

Use a spark plug socket to remove the old spark plug.

Install the new spark plug and reattach the ignition coil or wire.

Reconnect the battery and start the engine to check for improvements.

Fixing a Vacuum Leak

Use a smoke machine to identify the source of the leak.

Replace the damaged hose or gasket.

Recheck for leaks to ensure the issue is resolved.

Regular maintenance of the ignition system, including timely replacement of spark plugs and wires.

Routine inspection and cleaning of fuel injectors.

Regular engine compression tests to detect mechanical issues early.

Periodic checks and cleaning of sensors to ensure accurate readings.

| Maintenance Task | Recommended Frequency |

|---|---|

| Ignition System Maintenance | Replace spark plugs every 30,000 miles or as recommended by the manufacturer. |

| Fuel System Maintenance | Use fuel additives to keep injectors clean and replace the fuel filter every 15,000 miles. |

| Engine Mechanical Maintenance | Perform a compression test annually to check for worn components. |

| Sensor Maintenance | Clean the mass airflow sensor every 20,000 miles to ensure accurate air-fuel mixture readings. |

Diagnosing the exact cause of a misfire can be complex due to the numerous potential factors.

Intermittent misfires can be particularly challenging to identify and fix.

Some repairs, such as replacing a head gasket, can be labor-intensive and costly.

The age and overall condition of the vehicle can affect the likelihood of certain issues.

Environmental factors, such as extreme temperatures, can exacerbate certain problems.

The quality of replacement parts can impact the longevity and effectiveness of repairs.

Some may argue that regular maintenance is costly and time-consuming, but it can prevent more expensive repairs in the long run.

There is a debate over the effectiveness of aftermarket parts versus OEM parts, with some preferring the reliability of OEM components.

Understanding the causes, repair techniques, preventive measures, and challenges associated with the P0311 code is essential for maintaining vehicle performance and preventing further damage.

Regular maintenance and timely repairs can prevent misfires and ensure the longevity of your vehicle. Addressing issues early can save time and money in the long run.

Don't let a misfire leave you stranded. Stay proactive with your vehicle maintenance, and keep your engine running smoothly. If you encounter a P0311 code, take action immediately to diagnose and fix the issue, ensuring a safe and reliable driving experience.

A P0311 code indicates a misfire in cylinder 11 of your engine, which can lead to performance issues and should be addressed promptly.

Common symptoms include an illuminated check engine light, rough idling, and poor engine performance.

Causes can include faulty spark plugs, ignition coils, fuel injectors, or issues with the engine control module (ECM).

Diagnosis involves checking the spark plug, ignition coil, and fuel injector for cylinder 11, and possibly using an OBD-II scanner.

Driving with a P0311 code is not recommended as it can cause further engine damage.

Fixes may include replacing the spark plug, ignition coil, or fuel injector for cylinder 11, and ensuring proper fuel delivery.

Repair costs can vary but typically range from $100 to $300, depending on the specific issue and labor rates.

Yes, a misfire can lead to decreased fuel efficiency and increased emissions.

Regular maintenance, including timely replacement of spark plugs and fuel system checks, can help prevent misfires.

Yes, it is serious and should be addressed promptly to avoid further engine damage.

Miguel started tinkering with car radios as a teenager, fascinated by the intricate dance of wires and circuits. This passion led him to pursue a career as an automotive electrician. For the past 10 years, Miguel has tackled everything from flickering headlights to mysterious electrical gremlins. He thrives on troubleshooting electrical problems and enjoys sharing his knowledge to empower car owners to understand their vehicles better.