The diagnostic trouble code (DTC) P03AC indicates an issue with the cylinder 3 pressure sensor circuit in the engine management system. This code specifically means that the pressure sensor circuit for cylinder 3 is detecting a higher than expected voltage signal.

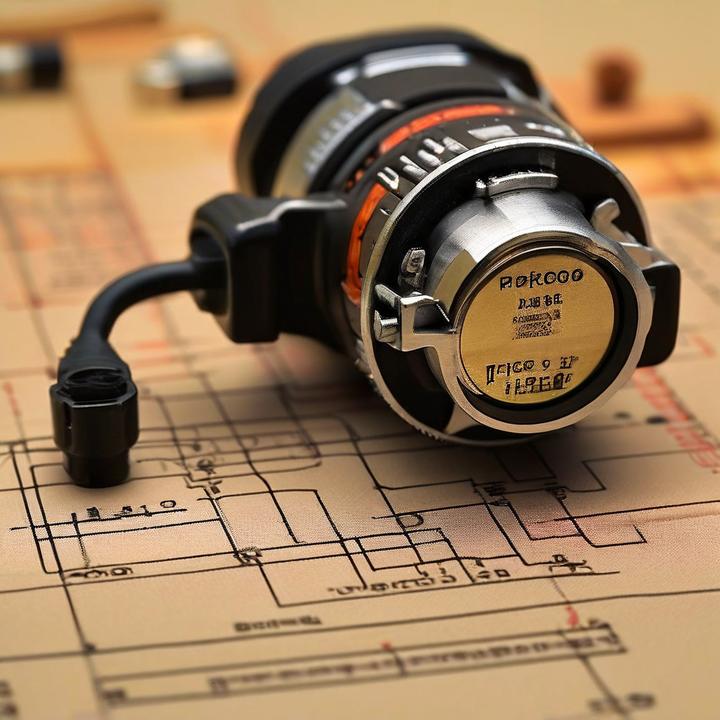

Before we get our hands dirty, let's first demystify what this code is all about. The P03AC code is a diagnostic trouble code (DTC) that indicates an issue with the pressure sensor circuit for cylinder 3 in your engine's combustion chamber. This sensor plays a pivotal role in monitoring the combustion pressure within that specific cylinder, and when something goes awry, your vehicle's computer throws this code to alert you of a potential problem.

Now, let's explore the usual suspects behind this pesky code. As with most automotive issues, there are a few common causes that we need to consider:

| Cause | Description |

|---|---|

| Faulty Pressure Sensor | The pressure sensor itself could be defective due to contamination, physical damage, or internal failure, leading to erratic or unchanging pressure readings. |

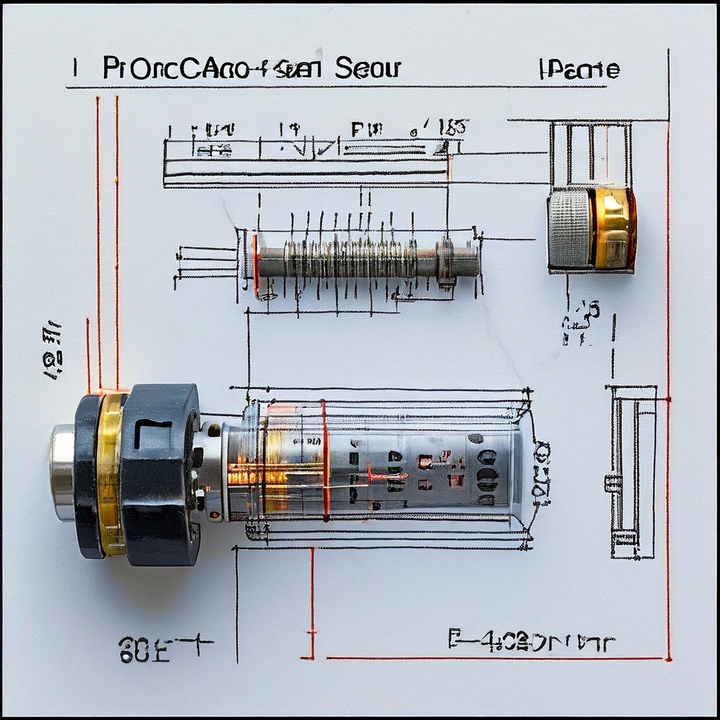

| Wiring Issue | A short circuit to power in the sensor wiring can cause excessively high voltage, triggering this code. An open circuit will also prevent the sensor from functioning properly. |

| Wiring Damage | Chafed, burnt, or broken wires in the harness, or corroded/damaged connectors can lead to electrical issues with the sensor circuit. |

Now that we know the potential culprits, it's time to put on our detective hats and dive into the diagnostic process. Here's how we can narrow down the cause:

First things first, we need to give the wiring harness and connectors a thorough once-over. Look for any signs of damage, such as:

Chafing

Burns

Corrosion

This simple step can often reveal the root cause of the problem.

Next, we'll break out our trusty multimeter and perform some electrical tests on the pressure sensor circuit:

| Test | Purpose |

|---|---|

| Voltage Test | Check for proper voltage supply and ground at the sensor connector. |

| Resistance Test | Test for any shorts or open circuits in the wiring. |

If the initial tests don't reveal anything conclusive, we can fire up our scan tool and monitor the live pressure sensor data. This will allow us to see if the sensor readings correlate with the engine's operating conditions, helping us determine if the sensor itself is faulty or if there's a wiring issue.

Once we've identified the root cause, it's time to roll up our sleeves and get to work. Here's what the repair process might entail:

If the pressure sensor itself is the culprit, we'll need to replace it. This typically involves:

Disconnecting the battery negative terminal.

Removing the glow plug/pressure sensor assembly from cylinder 3.

Installing a new pressure sensor assembly.

Reconnecting all components.

Clearing the trouble code and testing for proper operation.

In the case of wiring issues, we'll need to locate and repair any damaged wiring or connectors in the pressure sensor circuit. This might involve:

Splicing in new wires

Replacing connectors

Running a new wiring harness (if the damage is extensive)

Proper routing and protection of the wiring harness are crucial to prevent future issues.

As with any automotive repair, prevention is key to avoiding costly repairs down the line. Here are a few tips to keep in mind:

Follow the manufacturer's recommended service intervals for inspecting and replacing components as needed. Regular maintenance can help catch potential issues before they become major problems.

| Maintenance Task | Frequency |

|---|---|

| Engine Oil Change | Every 5,000 miles or as recommended |

| Air Filter Replacement | Every 12,000 miles or as recommended |

| Spark Plug Replacement | Every 30,000 miles or as recommended |

Avoid excessive idling or high engine loads that could lead to sensor contamination or damage. Treat your vehicle with care, and it will reward you with reliable performance.

Limit idling time

Avoid aggressive driving

Follow the recommended towing/hauling guidelines

Ensure that the wiring harness is properly secured and protected from potential damage sources, such as:

Heat

Abrasion

Environmental factors (moisture, debris, etc.)

As for the cost of repairs, it can vary depending on the specific cause and the labor rates in your area. Replacing just the pressure sensor itself may cost around $100-$300, while more extensive wiring repairs or an ECM replacement could be significantly higher. It's always a good idea to get a quote from a qualified repair shop after proper diagnosis.

Well, there you have it, folks! We've explored the depths of the P03AC - Cylinder 3 Pressure Sensor Circuit High code, from its causes to diagnostic procedures and repair methods. While this code may seem daunting at first, with the right knowledge and tools, it's just another puzzle waiting to be solved.

Remember, preventive maintenance and proper usage are key to avoiding these types of issues in the first place. But when trouble does strike, don't panic – just follow the diagnostic steps, and you'll be back on the road in no time.

Happy wrenching, my fellow automotive enthusiasts! Until next time, keep those engines purring and those codes at bay.

The most common symptoms include rough idling, misfiring, poor acceleration, and decreased fuel efficiency. The check engine light will also be illuminated.

While you can still drive, it's not recommended as the misfiring cylinder can cause further damage. Get it diagnosed and repaired as soon as possible.

Perform voltage and resistance tests on the sensor circuit. Erratic readings point to a faulty sensor, while constant high voltage or no reading indicates a wiring problem.

Yes, if the wiring harness is damaged, you can replace just that section related to the cylinder 3 pressure sensor circuit.

There is no set interval, but most manufacturers recommend replacing it every 60,000-100,000 miles as preventive maintenance.

Continued driving can lead to catalytic converter damage, increased emissions, and potential engine damage from the misfiring cylinder.

You can clear the code after repairs, but it will likely return if the underlying issue isn't resolved. Proper diagnosis and repair are recommended.

No, faulty spark plugs won't directly cause this code, but they can contribute to misfiring which may set other cylinder-specific codes.

Most replacements only require basic hand tools, but you may need a torque wrench to properly tighten the sensor to specifications.

Ensure proper routing and protection of wiring harnesses, use cable ties or loom to prevent chafing, and inspect regularly for any signs of damage.

Miguel started tinkering with car radios as a teenager, fascinated by the intricate dance of wires and circuits. This passion led him to pursue a career as an automotive electrician. For the past 10 years, Miguel has tackled everything from flickering headlights to mysterious electrical gremlins. He thrives on troubleshooting electrical problems and enjoys sharing his knowledge to empower car owners to understand their vehicles better.