The diagnostic trouble code P03BE indicates an issue with the cylinder 5 pressure sensor circuit range or performance. This code is related to the cylinder pressure monitoring system, which is used in modern engines for closed-loop combustion control and diagnostics.

Before we dive into the nitty-gritty of the P03BE code, let's take a moment to appreciate the unsung hero of our story – the cylinder pressure sensor. This little marvel is integrated into the glow plug assembly of diesel engines, and its primary function is to monitor the combustion pressure within each cylinder.

| Sensor Function | Description |

|---|---|

| Pressure Monitoring | The pressure sensor keeps a watchful eye on the pressure readings within each cylinder during the combustion process. |

| Real-time Adjustments | By monitoring these pressure readings, the engine control module (ECM) can make real-time adjustments to ensure optimal performance and efficiency. |

By keeping a close eye on these pressure readings, the ECM can make real-time adjustments to ensure optimal performance and efficiency, maximizing fuel economy and minimizing emissions.

Now, let's get down to business and explore the three main suspects that could be triggering the P03BE code:

Just like any other component, the pressure sensor for cylinder 5 can develop issues over time. Whether it's due to wear and tear, exposure to extreme temperatures, or simply a manufacturing defect, a faulty sensor can send incorrect readings to the ECM, causing it to raise the dreaded P03BE flag.

Common symptoms of a faulty cylinder 5 pressure sensor include:

Rough idling

Decreased fuel efficiency

Increased emissions

Engine performance issues

Ah, the age-old nemesis of every mechanic – wiring issues. An open circuit, a short circuit, or even a loose connection in the wiring harness connecting the cylinder 5 pressure sensor to the ECM can disrupt the flow of information, leading to the P03BE code rearing its ugly head.

Potential wiring issues can manifest in various ways, such as:

Intermittent sensor readings

Erratic engine behavior

Electrical system malfunctions

In some rare cases, the culprit might not be the sensor or the wiring but rather the ECM itself. If the ECM is experiencing issues, it may misinterpret or improperly process the signals from the cylinder 5 pressure sensor, resulting in the P03BE code being triggered.

Symptoms of an ECM malfunction can include:

Multiple diagnostic trouble codes

Erratic engine performance

Failure to respond to diagnostic procedures

Now that we've identified the potential suspects, it's time to roll up our sleeves and dive into the diagnostic process. Here's how we can go about troubleshooting the P03BE code:

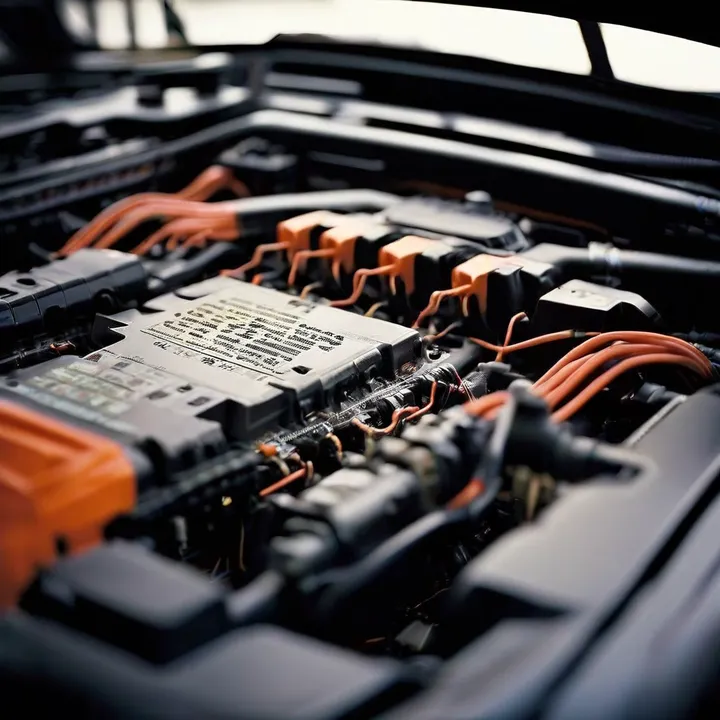

Start by giving the wiring harness and connectors a thorough once-over. Look for any signs of damage, corrosion, or loose connections that could be causing issues with the cylinder 5 pressure sensor circuit.

Inspect the wiring harness for any visible damage, such as cuts, abrasions, or chafing.

Check the connectors for signs of corrosion, moisture intrusion, or loose pins.

Ensure that all connections are secure and properly seated.

Break out your trusty multimeter and check for proper voltage supply and ground at the sensor connector. Additionally, perform a resistance test on the pressure sensor itself to ensure it's within the specified range.

| Test | Expected Value |

|---|---|

| Voltage Supply | Refer to manufacturer's specifications |

| Ground Circuit | Continuity to ground |

| Sensor Resistance | Within the specified range (consult service manual) |

Sometimes, the P03BE code can be triggered by an intermittent issue. In such cases, clear the code and take the vehicle for a test drive. If the code returns, you know you're dealing with a persistent problem that requires further investigation.

Clear the diagnostic trouble code using a scan tool or by disconnecting the battery.

Take the vehicle for a test drive, ensuring that the driving conditions are varied (highway, city, etc.).

Monitor for the reappearance of the P03BE code or any related symptoms.

Once you've identified the root cause of the P03BE code, it's time to roll up your sleeves and get to work. Here are the typical repair procedures:

If the pressure sensor for cylinder 5 is found to be faulty, it's time for a replacement. This typically involves removing the glow plug and installing a new sensor/glow plug assembly.

Follow the manufacturer's instructions for safely removing the glow plug and pressure sensor assembly.

Ensure that the new sensor is properly installed and seated correctly.

Reconnect all wiring and connectors securely.

In the case of wiring faults, you'll need to repair or replace the damaged wiring harness or connectors as needed.

Locate and isolate the faulty wiring section or connector.

Replace or repair the damaged components, following proper wiring practices and using high-quality materials.

Ensure that all connections are secure and properly insulated.

In the rare instance that the ECM itself is the culprit, you'll need to replace it. This is a more complex and costly repair, but it's sometimes necessary to restore proper functionality to the engine management system.

Follow the manufacturer's instructions for safely removing and replacing the ECM.

Ensure that all wiring connections are properly secured and routed.

After installation, the ECM may need to be programmed or initialized using specialized diagnostic tools.

As the old saying goes, "an ounce of prevention is worth a pound of cure." To avoid encountering the P03BE code and other related issues, it's crucial to follow a few simple maintenance guidelines:

Stick to the recommended maintenance schedule for inspecting and replacing glow plugs and related components. This preventative measure can help catch potential issues before they escalate.

Consult the owner's manual or service schedule for recommended intervals.

Replace glow plugs and pressure sensors at the specified mileage or time intervals.

Ensure that your engine is operating under optimal conditions, with adequate coolant levels, proper air flow, and high-quality fuel. These factors can significantly impact the longevity of sensors and other components.

Regularly check and top up coolant levels as needed.

Inspect and replace air filters according to the maintenance schedule.

Use high-quality diesel fuel from reputable sources.

Regular fuel system maintenance, such as replacing fuel filters and following the recommended service intervals, can help prevent contaminants from entering the system and potentially damaging sensitive components like pressure sensors.

Replace fuel filters at the recommended intervals.

Ensure that the fuel system is free from water contamination or debris.

Now, let's address the elephant in the room – the cost of repairs. The expenses associated with resolving the P03BE code can vary widely depending on the specific cause and the labor rates in your area.

| Repair | Typical Cost Range |

|---|---|

| Replacing Cylinder 5 Pressure Sensor/Glow Plug Assembly | $100 - $300 |

| Wiring Repairs | Varies based on extent of damage and labor rates |

| ECM Replacement | $500 - $1,500 or more |

It's important to note that these cost ranges are approximate and can vary significantly based on the make and model of your vehicle, as well as the labor rates in your area. Additionally, some repairs may require additional diagnostic fees or miscellaneous charges.

Well, there you have it, folks – a comprehensive guide to the P03BE code and all its intricacies. While it may seem like a daunting issue at first, with the right knowledge and a bit of elbow grease, you can tackle this automotive challenge head-on.

Remember, prevention is key, so stay on top of your maintenance game, and you'll be less likely to encounter this pesky code in the first place. By following the manufacturer's recommendations, maintaining optimal operating conditions, and staying vigilant with fuel system maintenance, you can minimize the risk of encountering the P03BE code and keep your diesel engine running smoothly.

Until next time, keep those engines purring and those diagnostic codes at bay!

The cylinder pressure sensor monitors the combustion pressure within each cylinder. It allows the engine control module (ECM) to make real-time adjustments for optimal performance and efficiency.

Common symptoms include rough idling, decreased fuel efficiency, increased emissions, and engine performance issues.

Yes, an open circuit, short circuit, or loose connection in the wiring harness connecting the cylinder 5 pressure sensor to the ECM can trigger the P03BE code.

It is diagnosed by visually inspecting the wiring, checking voltage and resistance at the sensor connector, and performing a drive cycle to monitor if the code returns.

The repair involves removing the glow plug and installing a new sensor/glow plug assembly, following the manufacturer's instructions.

In rare cases, a malfunctioning ECM that misinterprets or improperly processes the sensor signals can trigger the P03BE code.

Following the recommended maintenance schedule for inspecting and replacing glow plugs and related components can help prevent this code.

The cost can vary, but replacing just the cylinder 5 pressure sensor/glow plug assembly may cost around $100-$300, while replacing the ECM can be significantly more expensive.

Yes, regular fuel system maintenance, such as replacing fuel filters and following recommended service intervals, can help prevent contaminants from damaging sensitive components like pressure sensors.

Not necessarily. In some cases, only the damaged section of the wiring harness or connectors needs to be repaired or replaced.

Miguel started tinkering with car radios as a teenager, fascinated by the intricate dance of wires and circuits. This passion led him to pursue a career as an automotive electrician. For the past 10 years, Miguel has tackled everything from flickering headlights to mysterious electrical gremlins. He thrives on troubleshooting electrical problems and enjoys sharing his knowledge to empower car owners to understand their vehicles better.