A clutch is a crucial component in a manual transmission vehicle that allows the engine to be temporarily disconnected from the transmission, enabling smooth gear changes. When the clutch is fully engaged, it transfers the engine's power to the transmission, propelling the vehicle forward. However, when the clutch fails to disengage completely, a condition known as "clutch drag" occurs, leading to various issues and potential damage to the transmission.

Clutch drag can arise from various issues, ranging from simple adjustments to more complex component failures. Here are the main culprits:

| Cause | Description |

|---|---|

| Excessive Clutch Pedal Free Play | As the clutch disc wears down, the pressure plate fingers rise, reducing the clearance between them and the release bearing. If the clutch linkage (cable or hydraulic) is not adjusted properly, the release bearing may remain in constant contact with the pressure plate fingers, causing drag. |

| Maladjusted Clutch Linkage or Hydraulic System | Improper adjustment of the clutch cable or hydraulic system can prevent the clutch from fully disengaging when the pedal is pressed, leading to clutch drag and difficulty shifting gears smoothly. |

| Air in the Hydraulic Clutch System | Air pockets in the hydraulic lines or cylinders can cause the clutch to not disengage fully, resulting in clutch drag. This issue can lead to inconsistent clutch pedal feel and unpredictable clutch engagement. |

| Worn or Damaged Clutch Components | A worn-out clutch disc, warped pressure plate, or faulty release bearing can cause the clutch to not disengage properly, leading to drag. These components are subject to wear and tear over time, and their deterioration can significantly impact clutch performance. |

| Misalignment of Transmission or Clutch Housing | If the transmission or clutch housing is misaligned due to loose bolts or debris between mounting faces, it can cause the clutch components to bind or stick, resulting in clutch drag. |

As the clutch disc wears down over time, the pressure plate fingers rise, reducing the clearance between them and the release bearing. If the clutch linkage (cable or hydraulic) is not adjusted properly, the release bearing may remain in constant contact with the pressure plate fingers, causing drag.

This excessive free play in the clutch pedal is a common cause of clutch drag. When the clutch pedal has too much free play, it can prevent the clutch from fully disengaging, leading to slippage and difficulty shifting gears.

The clutch linkage, whether it's a cable or hydraulic system, plays a crucial role in transmitting the motion from the clutch pedal to the clutch components. If this linkage is not adjusted correctly, it can prevent the clutch from fully disengaging when the pedal is pressed.

In a cable-operated clutch system, the cable may be too tight or too loose, preventing the release bearing from fully disengaging the clutch. In a hydraulic clutch system, issues such as air pockets, leaks, or faulty components can cause the clutch to not disengage properly.

If your vehicle has a hydraulic clutch system, air pockets in the hydraulic lines or cylinders can be a significant cause of clutch drag. When air gets trapped in the system, it can create a spongy or inconsistent pedal feel, and prevent the clutch from fully disengaging.

Air can enter the hydraulic system due to various reasons, such as leaks, improper bleeding procedures, or worn seals. This issue can be particularly problematic as it can lead to unpredictable clutch engagement and potential damage to the clutch components.

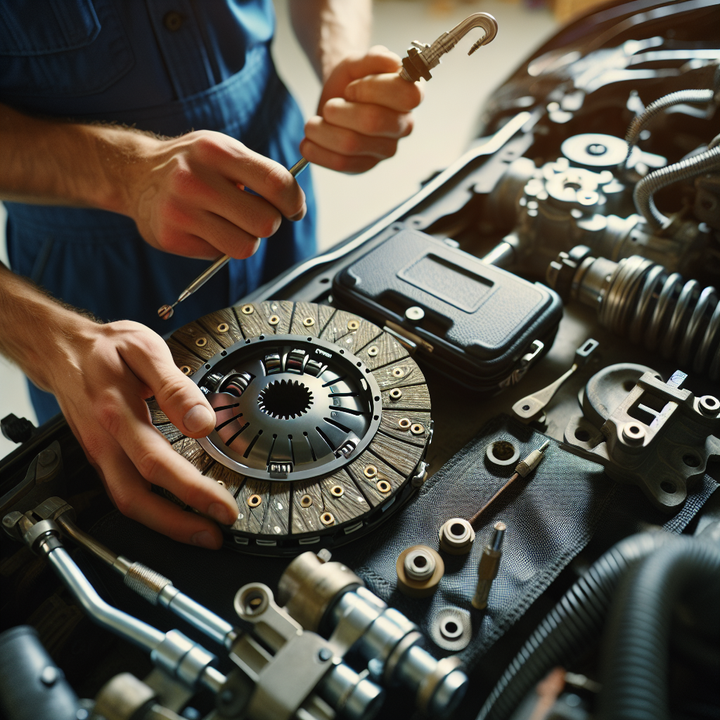

The clutch disc, pressure plate, and release bearing are critical components that work together to engage and disengage the clutch. Over time, these components can wear out or become damaged, leading to clutch drag and other issues.

A worn-out clutch disc can develop grooves or glazing, preventing it from fully disengaging from the flywheel. A warped or damaged pressure plate can cause uneven clamping force, leading to clutch drag or slippage. Similarly, a faulty release bearing can prevent the pressure plate from fully releasing the clutch disc, resulting in drag.

Proper alignment of the transmission and clutch housing is crucial for the smooth operation of the clutch components. If these components are misaligned due to loose bolts, debris between mounting faces, or impact damage, it can cause the clutch components to bind or stick, resulting in clutch drag.

Misalignment can occur due to various reasons, such as improper installation, wear and tear on the mounting points, or even after a transmission or clutch replacement if not properly aligned.

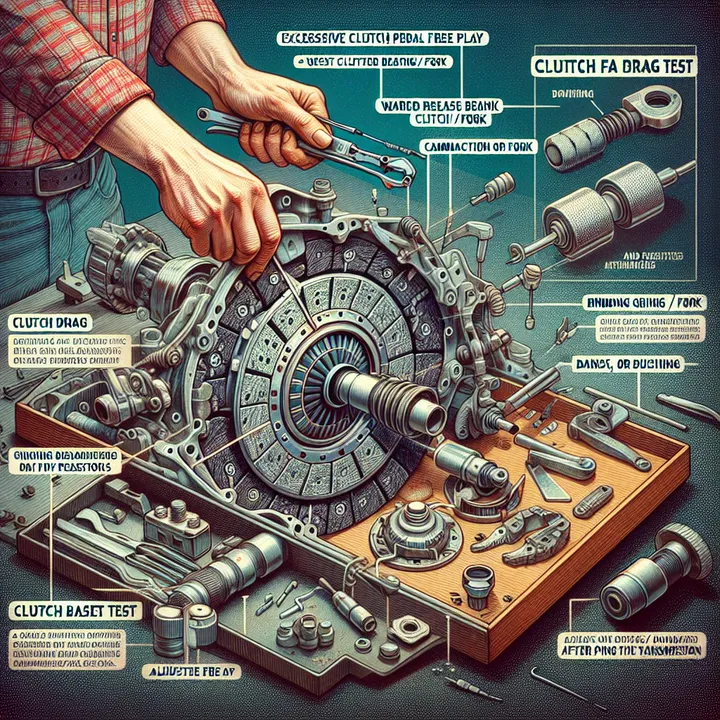

To accurately diagnose the cause of clutch drag, a thorough inspection is necessary. Here are the steps I typically follow:

Check clutch pedal free play and adjust if necessary: Start by checking the clutch pedal free play according to the manufacturer's specifications. If it's excessive, adjust the clutch linkage (cable or hydraulic) to restore proper free play.

Inspect clutch linkage (cable or hydraulic system) for proper adjustment, leaks, or damage: Examine the clutch linkage for any signs of wear, damage, or improper adjustment. Check for leaks in the hydraulic system if applicable.

Bleed the hydraulic clutch system to remove any air pockets: If your vehicle has a hydraulic clutch system, bleed the system to remove any air pockets that may be causing inconsistent clutch engagement.

Visually inspect clutch components (disc, pressure plate, release bearing) for wear or damage: Remove the transmission or clutch housing cover to inspect the clutch components. Look for signs of excessive wear, warping, or damage that could be causing clutch drag.

Check for misalignment of transmission or clutch housing: Inspect the mounting points and bolts that secure the transmission or clutch housing. Look for any signs of misalignment, loose bolts, or debris that could be causing binding or sticking of the clutch components.

During the inspection process, I also look for specific signs that can help pinpoint the root cause of the clutch drag:

Excessive clutch pedal free play: If the pedal must travel too far before disengaging, it's likely due to excessive free play in the linkage.

Maladjusted linkage: Difficulty shifting gears or the clutch not disengaging fully can indicate a maladjusted linkage.

Air in hydraulic system: A spongy or inconsistent clutch pedal feel can be a sign of air pockets in the hydraulic system.

Worn clutch components: Slipping, chattering, or dragging when engaging or disengaging the clutch can indicate worn or damaged components.

Misalignment: Binding or sticking clutch components, as well as unusual noises, can be caused by misalignment of the transmission or clutch housing.

Once the root cause of the clutch drag has been identified, the appropriate repairs can be made. Here's how I typically address each specific issue:

| Cause | Repair Procedure |

|---|---|

| Excessive Clutch Pedal Free Play | - Adjust the clutch linkage (cable or hydraulic) according to the manufacturer's specifications to restore proper free play. - If adjustment is insufficient, replace the stretched or damaged clutch cable. |

| Maladjusted Clutch Linkage or Hydraulic System | - Adjust the clutch cable or hydraulic system following the service manual's instructions. - Bleed the hydraulic system to remove any air pockets. - Replace faulty components (master/slave cylinders, hydraulic lines) if necessary. |

| Air in the Hydraulic Clutch System | - Bleed the hydraulic clutch system following the proper procedure to remove air pockets. - Check for leaks and replace faulty components (lines, cylinders, seals) if needed. |

| Worn or Damaged Clutch Components | - Replace the worn clutch disc, pressure plate, release bearing, or any other damaged parts. - Ensure proper alignment and adjustment after replacement to prevent premature wear. |

| Misalignment of Transmission or Clutch Housing | - Check and tighten any loose bolts or remove debris between the mounting faces. - Realign the transmission or clutch housing according to the manufacturer's specifications. |

When performing these repairs, it's crucial to follow the vehicle's service manual for proper procedures and torque specifications. Additionally, using high-quality replacement parts from reputable suppliers is essential to ensure longevity and proper clutch operation.

To minimize the likelihood of clutch drag recurring, regular maintenance and proper usage are key:

Inspect clutch components during scheduled maintenance intervals.

Adjust the clutch linkage or bleed the hydraulic system as needed.

Replace clutch components (disc, pressure plate, bearings) at the recommended intervals.

| Maintenance Task | Frequency |

|---|---|

| Inspect clutch components | Every 30,000 miles or as recommended |

| Adjust clutch linkage or bleed hydraulic system | As needed, based on inspection |

| Replace clutch components | Every 60,000 - 100,000 miles or as recommended |

Avoid resting your foot on the clutch pedal while driving, as this can cause premature wear.

Don't slip the clutch excessively or ride the clutch pedal, as this can lead to overheating and damage.

Allow the clutch to cool down after prolonged heavy use, such as towing or driving in stop-and-go traffic.

Shift gears smoothly and avoid harsh engagements to minimize wear on the clutch components.

By following these preventive measures, you can extend the life of your clutch and minimize the risk of clutch drag or other clutch-related issues.

The cost of repairing clutch drag can vary depending on the specific cause and the extent of the repairs required. Here are some general cost estimates:

| Repair | Cost Range |

|---|---|

| Clutch linkage adjustment or bleeding the hydraulic system | $100 - $300 (labor costs) |

| Replacing clutch cable or hydraulic components | $200 - $500 (parts and labor) |

| Replacing clutch disc, pressure plate, or release bearing | $500 - $1,200 (parts and labor) |

| Transmission or clutch housing realignment | $300 - $800 (labor-intensive) |

| Complete clutch replacement (disc, pressure plate, release bearing, etc.) | $800 - $1,500 (parts and labor) |

Note that these costs are approximate and can vary based on the make and model of the vehicle, the mechanic's labor rates, and any additional repairs required. It's always recommended to get a quote from a reputable mechanic or dealership for an accurate estimate.

Clutch drag can be a frustrating issue, but with proper diagnosis and repair, it can be resolved effectively. By understanding the main causes, such as excessive free play, maladjusted linkages, air in the hydraulic system, worn components, and misalignment, you can take the necessary steps to address the problem.

Regular maintenance and proper usage are key to preventing clutch drag and extending the life of your clutch components. If you experience any signs of clutch drag, don't hesitate to have it inspected by a qualified mechanic to avoid further damage and ensure a smooth and enjoyable driving experience.

Clutch slippage occurs when the clutch disc is not transferring power effectively from the engine to the transmission. Clutch drag happens when the clutch disc does not fully disengage, causing difficulty in shifting gears.

Yes, a stretched or damaged clutch cable can prevent the clutch from fully disengaging, leading to clutch drag.

Air pockets in the hydraulic lines or cylinders can cause the clutch to not disengage fully, resulting in clutch drag.

A worn or frozen pilot bearing can cause the input shaft to spin, leading to a rumbling or whining sound and clutch drag.

Yes, misalignment of the transmission or clutch housing due to loose bolts or debris can cause the clutch components to bind or stick, resulting in clutch drag.

If the clutch pedal has too much free play, the pressure plate may not fully disengage from the clutch disc, causing clutch drag.

Adjusting the clutch linkage or hydraulic system ensures that the clutch fully disengages when the pedal is pressed, preventing clutch drag.

Yes, a warped clutch disc or pressure plate can prevent the clutch from fully disengaging, leading to clutch drag.

Regular maintenance, such as inspecting and replacing worn clutch components, adjusting the clutch linkage, and bleeding the hydraulic system, can help prevent clutch drag.

Ignoring clutch drag can lead to premature wear and damage to the clutch components, transmission, and other related parts, resulting in costly repairs.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.