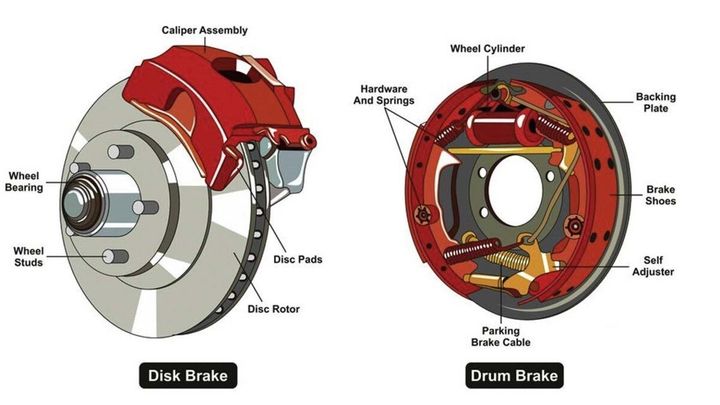

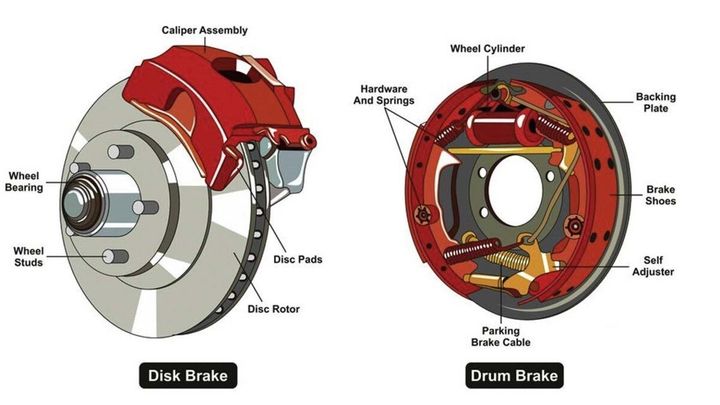

A disc brake is a type of brake system that uses calipers to squeeze pairs of brake pads against a rotating disc or rotor to create friction, slowing or stopping the motion of a vehicle's wheels. It consists of the following main components:

Brake disc or rotor: A flat, circular disc made of cast iron or composite materials, attached to the wheel hub and rotating with the wheel.

Brake caliper: A housing that contains the brake pads and hydraulic pistons, mounted on the steering knuckle or suspension upright.

Brake pads: Friction materials, typically made of metallic or ceramic compounds, that press against the disc when the brakes are applied.

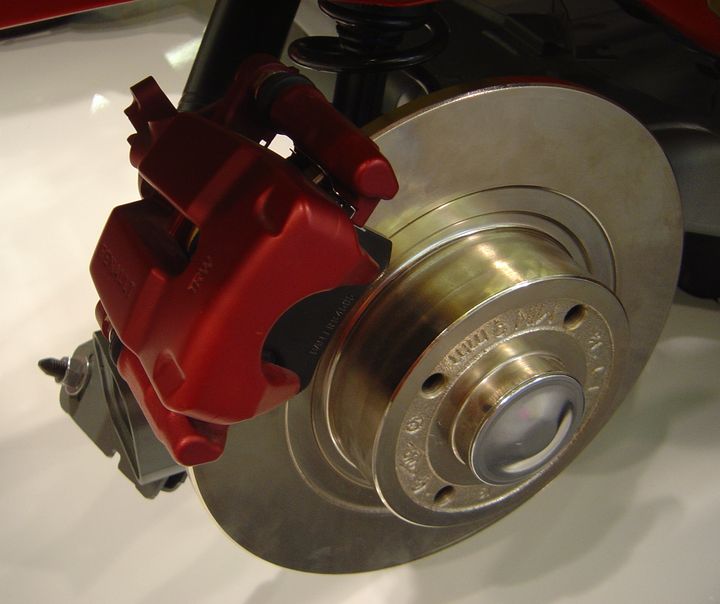

When the brake pedal is pressed, hydraulic pressure is applied to the pistons in the caliper, forcing the brake pads against the rotating disc. The resulting friction slows down the disc and the attached wheel, converting the vehicle's kinetic energy into heat energy.

Disc brakes are a type of brake system that utilizes calipers to squeeze pairs of brake pads against a spinning disc (or rotor) attached to the wheel. When you depress the brake pedal, hydraulic pressure is applied to the calipers, causing the brake pads to clamp down on the rotor. This friction between the pads and rotor creates the braking force that slows down or stops the vehicle.

Disc brakes are typically found on the front wheels of most vehicles, while some cars also have disc brakes on the rear wheels. They offer superior braking performance compared to drum brakes, especially in wet or high-heat conditions, making them the preferred choice for modern vehicles.

Over time, disc brakes can experience various issues that can affect their performance and safety. Let's explore some common problems I encounter:

| Problem | Causes |

|---|---|

| Brake Noise (Squealing/Squeaking) | Worn brake pads, stuck caliper sliders, glazed pads |

| Brake Noise (Grinding) | Severely worn pads down to the backing plate, damaged rotors |

| Brake Pulsation/Vibration | Warped/uneven rotors, brake pad deposit buildup |

| Reduced Braking Performance | Worn brake pads, contaminated pads/rotors, overheated components |

| Dragging Brakes | Stuck caliper piston, brake pad knock-back |

| Fluid Leaks | Damaged brake lines, caliper seal failure |

One of the most common complaints I hear from customers is brake noise. Squealing or squeaking noises can be caused by worn brake pads, stuck caliper sliders, or glazed (overheated) pads. A grinding noise, on the other hand, usually indicates that the brake pads are severely worn down to the backing plate or that the rotors are damaged.

If you feel a pulsation or vibration in the brake pedal when applying the brakes, it could be due to warped or unevenly worn rotors. This can be caused by overheating, poor quality rotors, or uneven pad wear. Another potential cause is brake pad deposit buildup, where glazed pads leave material deposits on the rotors.

If you notice that your vehicle takes longer to stop or the brake pedal feels spongy, it could be a sign of worn brake pads, contaminated pads or rotors (exposure to grease, oil, or brake fluid), or overheated components leading to brake fade.

Dragging brakes can be caused by stuck caliper pistons (due to corrosion or seizing) or brake pads that are not retracting fully off the rotor (known as pad knock-back). This can lead to premature wear, overheating, and reduced fuel efficiency.

Leaks in the brake system can be a serious issue, as they can lead to a loss of braking pressure and performance. Common causes include damaged brake lines (cracked, swollen, or chafed), or caliper seal failures, where the caliper piston seals start leaking brake fluid.

To properly diagnose disc brake issues, a thorough inspection is necessary. Here's what I typically do:

Check brake pads for minimum thickness (replace if below specs)

Inspect rotors for scoring, grooves, cracks, or uneven wear patterns

Look for signs of fluid leaks around calipers, lines, and wheel cylinders

Check caliper sliders for smooth operation and lubrication

Listen for abnormal noises during braking (squealing, grinding, etc.)

Feel for pulsation or vibration in the brake pedal when applied

Test brake pedal firmness and travel distance

Check parking brake function and adjustment

Measure rotor thickness with a micrometer (replace if below minimum)

Check rotor runout/lateral runout with a dial indicator (runout exceeding specs)

Perform a brake fluid inspection for contamination or moisture

Depending on the issue, various repair procedures may be required. Let's explore some common ones:

This is one of the most common repairs I perform. The process involves:

Safely raising and supporting the vehicle

Removing the wheel and caliper (avoiding depressing the caliper piston)

Removing the old brake pads and cleaning the caliper housing

Installing new brake pads as per the manufacturer's instructions

Reinstalling the caliper and components, pumping the brake pedal to set the pads

Repeating for all wheels, followed by a bedding procedure

In cases of excessive rotor wear or damage, rotor replacement is necessary. The steps include:

Following brake pad removal steps 1-3

Removing the caliper mounting bolts to free up the caliper and rotor

Removing the old rotor, cleaning the hub surface and caliper mounting areas

Installing a new rotor, ensuring proper fit and no runout issues

Reinstalling the caliper and new brake pads, pumping the brake pedal

Repeating for all wheels, followed by a bedding procedure for the new pads and rotors

If a caliper is sticking or leaking, an overhaul may be required. This involves:

Removing the caliper from the vehicle and draining the brake fluid

Disassembling the caliper, replacing seals, boots, and any damaged components

Cleaning all components with brake parts cleaner

Lubricating components as per the manufacturer's recommendations

Reassembling the caliper, reinstalling it on the vehicle, and bleeding the brakes

In cases of damaged or leaking brake lines or hoses, replacement is necessary. The process includes:

Safely depressurizing the brake system

Disconnecting the old line or hose at both ends

Installing a new line or hose, ensuring proper routing and no kinks

Bleeding the brakes to remove any air from the system

To keep your disc brakes in top condition and avoid costly repairs, preventive maintenance is crucial. Here are some tips:

| Maintenance Task | Description |

|---|---|

| Follow Replacement Intervals | Replace brake pads and rotors as per manufacturer's recommendations |

| Regular Inspections | Inspect brakes during tire rotations or oil changes for wear or issues |

| Brake Fluid Flush | Flush brake fluid as per the service schedule to prevent contamination |

| Avoid Excessive Heat | Avoid aggressive braking that can lead to overheating and premature wear |

| Keep Brakes Clean | Maintain a clean environment around the brakes, free of contaminants |

| Lubricate Components | Lubricate caliper sliders and hardware as needed for smooth operation |

Follow the recommended brake pad and rotor replacement intervals for your vehicle.

Regularly inspect your brakes during tire rotations or oil changes for any signs of wear or issues.

Flush the brake fluid as per the manufacturer's service schedule, as contaminated or moisture-laden fluid can degrade braking performance.

Avoid excessive heat buildup from aggressive braking, as this can lead to premature wear and damage.

Keep the area around the brakes clean and free of contaminants, such as road debris or grease.

Lubricate the caliper sliders and hardware as needed to ensure smooth operation.

The cost of disc brake repairs can vary depending on several factors, such as the vehicle type, labor rates in your area, and the quality of replacement parts used. Here are some typical cost ranges:

| Repair | Cost Range |

|---|---|

| Brake Pad Replacement | $100-$300 per axle (pads and labor) |

| Rotor Replacement | $150-$400 per axle (rotors and labor) |

| Caliper Overhaul | $100-$400 per caliper (parts and labor) |

| Brake Line or Hose Replacement | $100-$300 per line or hose |

| Brake Fluid Flush | $80-$150 (fluid and labor) |

It's important to address brake issues promptly, as neglecting them can lead to more expensive repairs down the line and compromise your safety on the road.

Disc brakes are a vital component of your vehicle's braking system, and understanding their operation, common issues, and maintenance requirements is crucial for ensuring your safety and the longevity of your car. By following the inspection, repair, and preventive maintenance practices I've outlined, you can keep your disc brakes in top condition and enjoy a smooth, safe driving experience.

Remember, if you ever encounter any brake-related issues or have concerns, don't hesitate to consult a professional mechanic. Proper maintenance and timely repairs can save you from costly repairs and potential accidents down the road.

Happy braking, and drive safely!

Disc brakes use calipers to squeeze brake pads against a spinning disc (rotor) to create friction and stop the vehicle. Drum brakes use brake shoes that press against the inside of a rotating drum to slow down the wheels.

You should replace brake pads when they are worn down to the minimum thickness specified by the manufacturer, or if you experience excessive brake noise, vibration, or reduced braking performance.

Brake rotors can warp or become uneven due to excessive heat buildup from aggressive braking, poor quality rotors, or uneven pad wear.

Bleeding the brakes after a repair is crucial to remove any air from the brake lines and ensure proper hydraulic pressure for optimal braking performance.

Brake fade is a reduction in braking performance due to overheated components. It can be prevented by avoiding excessive heat buildup from aggressive braking and maintaining proper brake system maintenance.

Lubricating caliper sliders and hardware ensures smooth operation of the caliper and prevents sticking or seizing, which can lead to uneven pad wear and reduced braking performance.

Brake fluid should be flushed according to the manufacturer's recommended service schedule, typically every 2-3 years or 30,000-60,000 miles, to prevent contamination and maintain optimal braking performance.

Signs of a leaking brake caliper include fluid leaks around the caliper area, a low brake fluid level in the master cylinder reservoir, and a soft or spongy brake pedal.

It is generally recommended to replace brake rotors in pairs (both front or both rear) to ensure even braking and prevent vibration or pulsation issues.

The bedding procedure involves a series of light brake applications at varying speeds to properly transfer a thin layer of pad material onto the new rotors, ensuring optimal braking performance and pad life.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.