Proper maintenance is crucial for ensuring the longevity and optimal performance of a vehicle's engine. One of the most fundamental aspects of engine maintenance is regularly checking and maintaining the appropriate level of engine oil. This task is facilitated by a simple yet essential component known as the dipstick.

Before we dive into the removal process, let's briefly discuss the importance of the dipstick. This simple yet crucial component serves as a gauge for checking the engine oil level, ensuring that your vehicle has the proper amount of lubricant to keep everything running smoothly. Without a functioning dipstick, you risk running your engine with insufficient oil, which can lead to costly damage.

| Dipstick Function |

|---|

| Checks engine oil level |

| Ensures proper lubrication |

| Prevents costly engine damage |

Over the years, I've encountered several reasons why dipsticks break. Here are the most common culprits:

| Cause | Explanation |

|---|---|

| Forcing the dipstick | Some dipsticks, especially on older cars, need to rotate slightly as you insert them into the tube. Forcing them in without allowing rotation can cause the dipstick to shear off or break. |

| Age and brittleness | Over time, the plastic dipstick can become brittle and break, especially if it's an older vehicle. |

| Improper removal | Yanking or pulling the dipstick out at an angle instead of straight up can cause it to break off inside the tube. |

If you suspect your dipstick might be broken, there are a few telltale signs to look for:

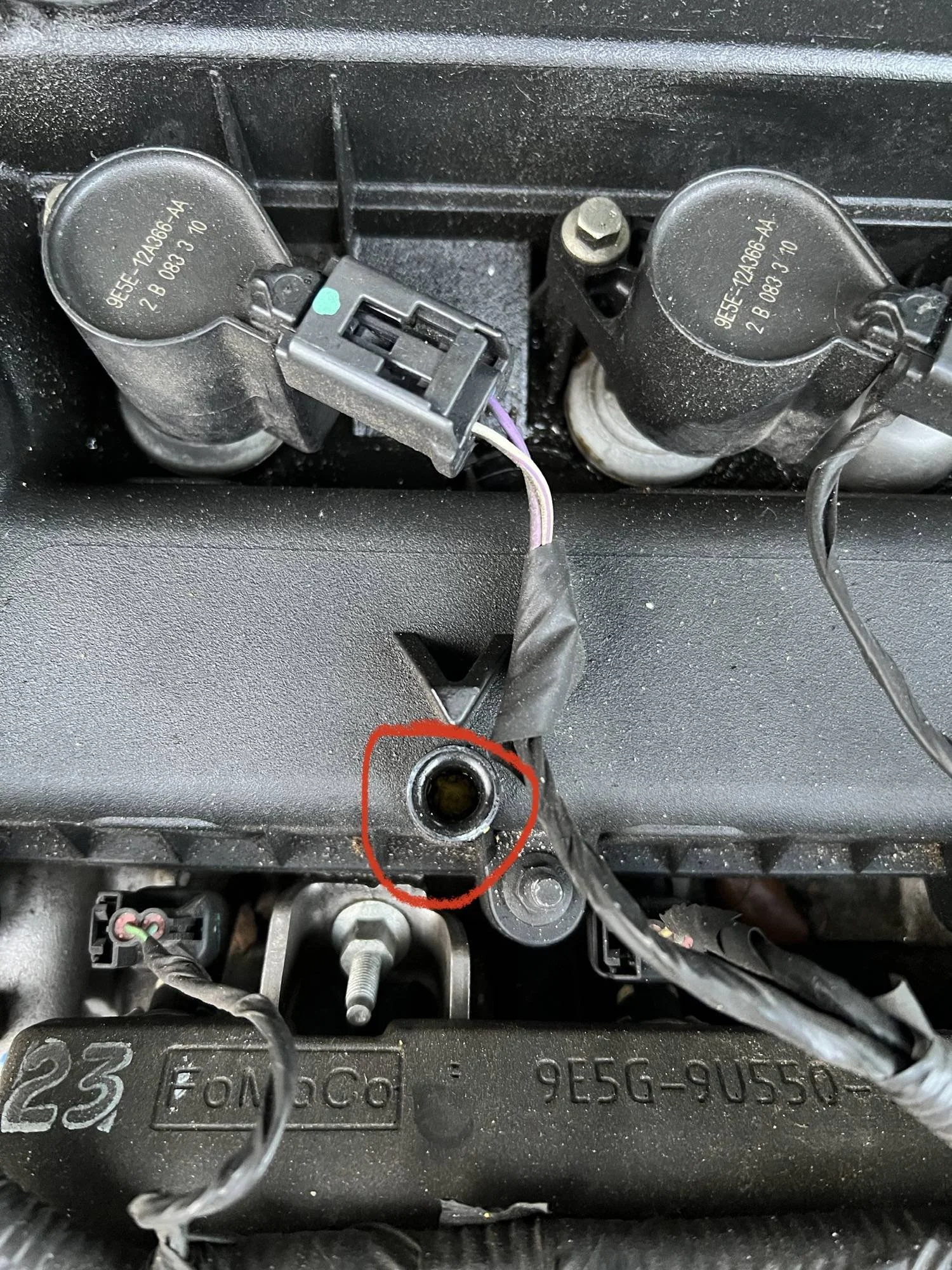

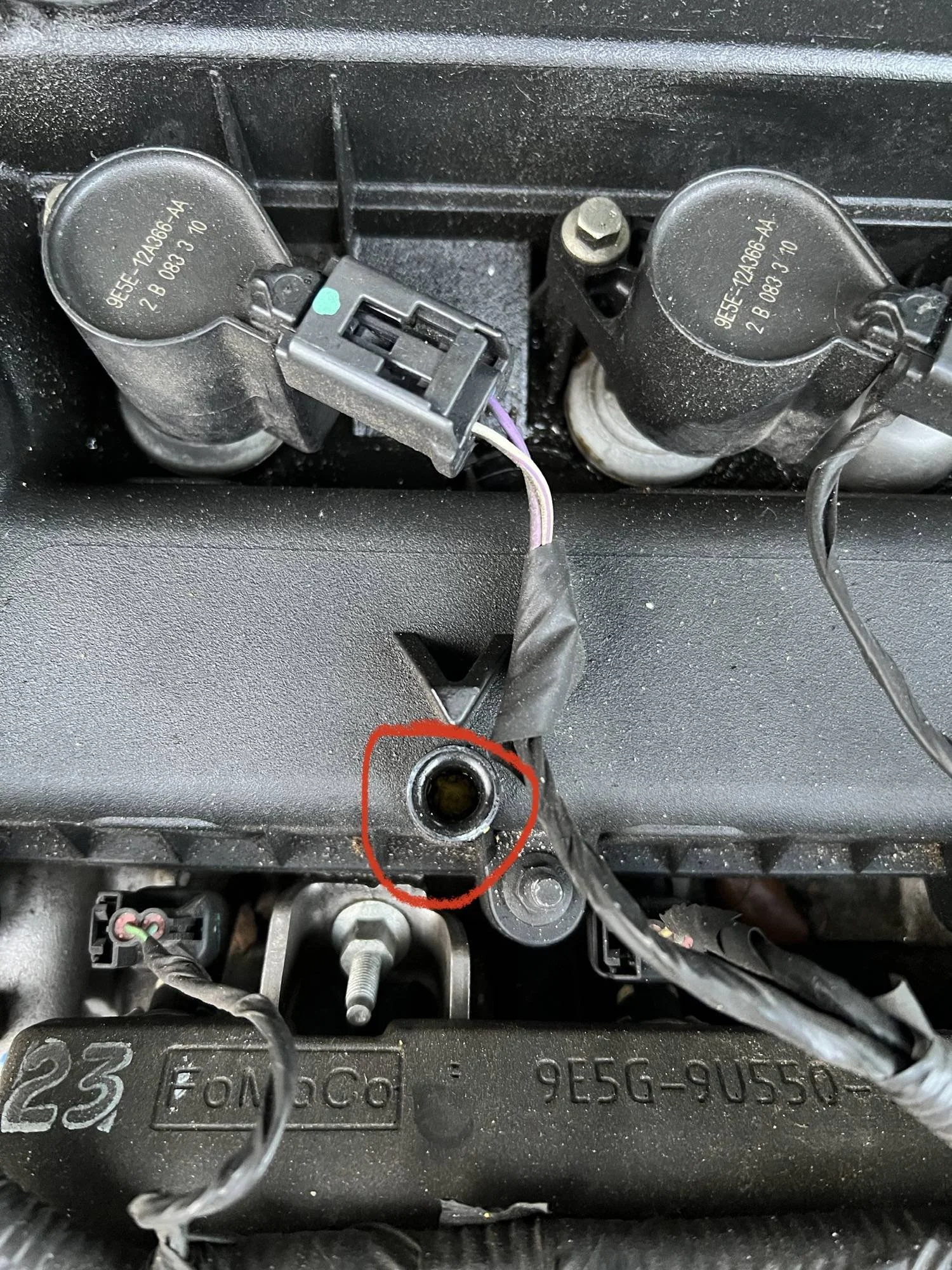

Look down the dipstick tube with a flashlight. If you can see part of the yellow or orange plastic handle still visible, it's likely that the dipstick has broken off inside the tube.

Try gently inserting a new dipstick. If it won't go all the way down, there are broken pieces obstructing the tube.

Now, let's get to the heart of the matter – removing that pesky broken dipstick. Over the years, I've developed several tried-and-true methods that have proven effective in various situations.

One of my go-to methods is using a hooked wire or tool. I'll often fashion a small hook from a wire coat hanger or a stiff piece of wire. Carefully, I'll insert it into the tube and try to hook and pull out the broken piece(s). This method requires a steady hand and a bit of patience, but it can be surprisingly effective, especially if the broken pieces are still relatively intact.

Here's a step-by-step guide for the hooked wire technique:

Locate a wire coat hanger or a stiff piece of wire.

Bend the end of the wire into a small hook shape.

Carefully insert the hooked end into the dipstick tube.

Gently move the hook around, trying to catch and pull out any broken pieces.

Repeat the process until all pieces are removed.

Another technique I've found useful is heating up a screw and pressing the hot tip into the remaining plastic handle stub. Once the screw has cooled and adhered to the plastic, I can then try pulling the screw and dipstick out with a pair of pliers. This method works best when there's still a sizable portion of the plastic handle remaining inside the tube.

Here's how to perform the hot screw trick:

Locate a screw that fits snugly into the remaining plastic handle stub.

Heat the screw tip with a lighter or torch until it's hot (but not glowing red).

Carefully press the hot screw tip into the plastic handle stub and allow it to cool.

Once cooled, use a pair of pliers to grip the screw and try pulling out the dipstick.

In more extreme cases, where the dipstick is well and truly stuck, I've had to resort to cutting the dipstick tube itself. Using a tubing cutter, I'll carefully cut the tube below where the dipstick is broken. This allows me to remove the entire tube and access the broken dipstick pieces directly. Once the pieces are removed, I'll reattach the cut portion of the tube using a strong epoxy like J-B Weld.

Here's the process for cutting the dipstick tube:

Locate a tubing cutter or a hacksaw (as a last resort).

Identify the location of the broken dipstick inside the tube.

Cut the tube below the broken dipstick, being careful not to damage surrounding components.

Remove the cut portion of the tube, exposing the broken dipstick pieces.

Extract the broken pieces carefully.

Reattach the cut portion of the tube using a strong epoxy like J-B Weld, following the manufacturer's instructions.

On some vehicles, you can unbolt the entire dipstick tube assembly from the engine block. This approach exposes the broken end of the dipstick, making it much easier to remove the pieces. However, it's important to note that this method may require more disassembly and should only be attempted if you're comfortable working on your vehicle's engine.

Here's how to remove the dipstick tube assembly:

Consult your vehicle's repair manual to locate the dipstick tube assembly.

Identify and remove any bolts or fasteners securing the assembly to the engine block.

Carefully remove the entire assembly, exposing the broken end of the dipstick.

Extract the broken pieces from the assembly.

Reassemble the dipstick tube assembly and secure it back in place.

If all else fails, and you've already drained the oil, you can try dropping a magnet tied to a wire or coat hanger into the drain hole. This technique can be useful for retrieving any ferrous metal pieces of the broken dipstick that may have fallen into the oil pan.

Here's how to use the magnet on a wire trick:

Drain the engine oil from the oil pan.

Locate a strong magnet and tie it securely to a wire or coat hanger.

Carefully lower the magnet into the drain hole, moving it around to attract any metal pieces.

Slowly retrieve the magnet, checking if any broken dipstick pieces are attached.

Repeat the process until all metal pieces are removed.

While dealing with a broken dipstick can be a frustrating experience, there are steps you can take to prevent it from happening in the first place.

| Prevention Tip | Explanation |

|---|---|

| Be gentle | When inserting and removing the dipstick, be gentle. If the dipstick needs to rotate, allow it to do so without forcing it. |

| Replace aging dipsticks | Replace brittle, aging dipsticks before they have a chance to break. |

| Inspect during oil changes | During regular oil changes, take a moment to inspect the dipstick for any signs of damage or wear. |

Removing a broken dipstick can be a challenging task, but with the right techniques and a bit of patience, it's certainly achievable. Whether you opt for the hooked wire method, the hot screw trick, cutting the tube, removing the entire assembly, or using a magnet on a wire, the key is to approach the situation methodically and with care.

Remember, a replacement dipstick is an inexpensive part, typically costing between $5 and $20 from the dealer or an auto parts store. So, if all else fails, replacing the dipstick entirely may be the most straightforward solution.

As a mechanic, I've learned that tackling automotive issues head-on and with a problem-solving mindset is crucial. With the knowledge and techniques shared in this article, you'll be better equipped to handle a broken dipstick and keep your vehicle running smoothly.

Understand the question fully and provide a focused, relevant response. Aim for a straightforward and easily understandable answer by avoiding unnecessary jargon or excessive details.

Use numbered lists, bullet points, or subheadings to break down complex concepts into digestible chunks. This helps readers navigate the information more efficiently.

Examples can greatly enhance understanding by illustrating points and providing real-world context. Relevant examples allow readers to grasp concepts more easily.

Anticipate additional questions readers may have and address them upfront. Providing comprehensive information can prevent the need for follow-up queries.

Planning and outlining help organize thoughts, structure arguments, and avoid including unnecessary or irrelevant information. It ensures a coherent flow and focused content.

Defining the purpose and audience determines the tone, style, format, and content of the document. It ensures the writing is tailored to effectively communicate with the intended readers.

Using visuals like images, videos, or infographics can make content more engaging and easier to understand. Incorporating expert insights or influencer collaborations can add credibility and authority.

Start with a hook that captures attention, provide background information, and include a clear thesis statement. A solid introduction sets the stage and makes a strong first impression.

Proofreading and editing ensure readability, catch grammar and spelling errors, and address inconsistencies in arguments. It improves the overall quality and clarity of the writing.

Track metrics like page views, bounce rate, and time spent on the page to evaluate performance. Continuously update content based on user feedback and emerging questions.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.