Among the vast array of high-performance engines, two standouts from General Motors have captured the hearts of enthusiasts worldwide – the LS3 and LS7. These 6.2-liter aluminum powerhouses represent the pinnacle of GM's iconic small-block V8 design, combining prodigious power with compact dimensions and lightweight construction. In this comprehensive guide, we'll delve into the intricate details that separate these two legends, exploring their performance capabilities, reliability, intended applications, and cost factors, ultimately determining which reigns supreme for your specific needs.

The LS-series of engines marked a significant departure from GM's traditional small-block V8 architecture. Introduced in 1997, these modern marvels featured an all-aluminum construction, overhead valve design, and a compact footprint, making them lighter and more efficient than their predecessors. The table below highlights the key differences between the traditional and LS-series small-block V8s:

| Characteristic | Traditional Small-Block | LS-Series |

|---|---|---|

| Block Material | Cast Iron | Aluminum |

| Valvetrain Design | Pushrod | Overhead Valve |

| Displacement Range | 4.3L - 6.0L | 4.8L - 7.0L |

| Weight | Heavier | Lighter |

| Efficiency | Lower | Higher |

Despite their cutting-edge engineering, the LS3 and LS7 pay homage to GM's legendary small-block lineage, tracing their roots back to the original 265 cubic-inch V8 introduced in 1955. This iconic platform has undergone continuous evolution, cementing its status as one of the most versatile and widely adopted V8 designs in automotive history. The table below illustrates the progression of GM's small-block V8 family:

| Generation | Introduction Year | Displacement Range |

|---|---|---|

| Gen I | 1955 | 265 - 400 cu in |

| Gen II | 1962 | 283 - 402 cu in |

| Gen III | 1997 | 4.8 - 6.0L |

| Gen IV | 2005 | 4.8 - 7.0L |

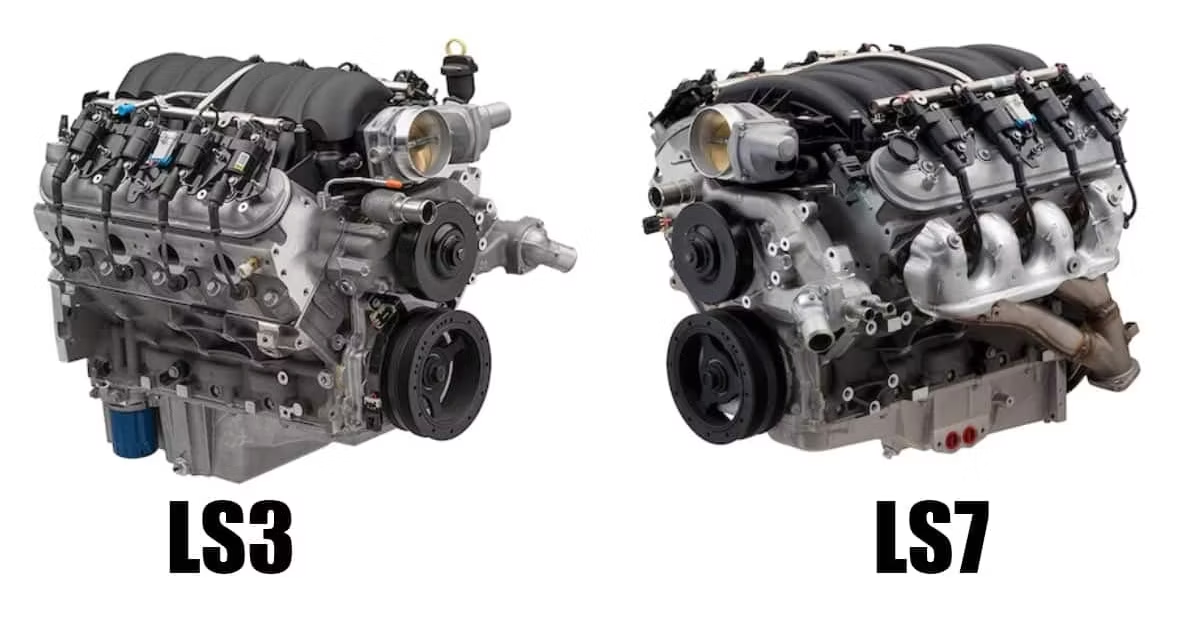

The LS3 and LS7 represent the pinnacle of GM's LS-series, both displacing 6.2 liters (376 cubic inches) and sharing the same aluminum block architecture. However, their distinct engineering philosophies and intended applications set them apart, making them the subject of heated debates among performance enthusiasts. The table below summarizes their key specifications:

| Specification | LS3 | LS7 |

|---|---|---|

| Displacement | 6.2L (376 cu in) | 6.2L (376 cu in) |

| Block Material | Aluminum | Aluminum |

| Valvetrain | Overhead Valve, Pushrod | Overhead Valve, Pushrod |

| Oiling System | Wet Sump | Dry Sump |

| Compression Ratio | 10.7:1 | 11.0:1 |

| Redline RPM | 6,600 rpm | 6,800 rpm |

The LS7 stands as the undisputed king of factory-rated horsepower, producing a staggering 505 hp at 6,300 rpm. In contrast, the LS3 is no slouch, delivering a respectable 430 hp at 5,900 rpm. When it comes to torque, the LS7 boasts an impressive 470 lb-ft at 4,800 rpm, while the LS3 holds its own with a robust 424 lb-ft at 4,600 rpm, showcasing its low-end grunt.

One of the LS7's defining characteristics is its lofty 6,800 rpm redline, enabling it to rev freely and extract maximum power from its high-revving nature. The LS3, while still capable, has a more modest 6,600 rpm redline. The table below summarizes the performance figures:

| Engine | Horsepower | Torque | Redline RPM |

|---|---|---|---|

| LS3 | 430 hp @ 5,900 rpm | 424 lb-ft @ 4,600 rpm | 6,600 rpm |

| LS7 | 505 hp @ 6,300 rpm | 470 lb-ft @ 4,800 rpm | 6,800 rpm |

The LS7's higher compression ratio of 11.0:1 (compared to the LS3's 10.7:1) contributes to its increased power output, enabling more efficient combustion and extracting more energy from each fuel-air mixture. Additionally, the LS7 features a more aggressive camshaft profile, optimized for high-rpm operation and increased airflow through its larger valves. This design prioritizes top-end power over low-end torque, which is the LS3's forte.

Complementing its high-revving nature, the LS7 boasts larger intake and exhaust valves, measuring 2.20 inches and 1.61 inches, respectively. The LS3's valves, while still substantial at 2.16 inches (intake) and 1.59 inches (exhaust), are slightly smaller, contributing to its lower redline. The table below compares the key engineering differences:

| Characteristic | LS3 | LS7 |

|---|---|---|

| Compression Ratio | 10.7:1 | 11.0:1 |

| Camshaft Profile | Moderate | Aggressive |

| Intake Valve Size | 2.16 in | 2.20 in |

| Exhaust Valve Size | 1.59 in | 1.61 in |

In naturally aspirated form, the LS3 can reliably produce up to 436 hp with bolt-on modifications, while the LS7 can reach an impressive 570 hp before encountering limitations. However, both engines respond exceptionally well to forced induction, with the LS7's higher airflow capabilities giving it an edge for serious boost levels.

Naturally Aspirated Limits:

LS3: Up to 436 hp

LS7: Up to 570 hp

Properly built and tuned, these powerplants can safely generate well over 700 hp with the right supporting modifications, such as:

Forced Induction (Supercharger or Turbocharger)

Upgraded Fuel System

Strengthened Internal Components

Improved Cooling System

Tuned Engine Management System

While generally robust, the LS3 is not immune to potential issues. Common problems include:

Oil Pump Failures

Piston Ring Wear (leading to high oil consumption)

Valve/Lifter Problems at Higher Mileages

However, with proper maintenance and quality parts, the LS3 can prove extremely reliable, even in high-performance applications. Its more conservative design and wet sump oiling system contribute to its durability.

The LS7's high-revving nature and increased stress levels make it more prone to certain issues, such as exhaust valve stem separation in some cases. However, the LS7's dry sump oiling system provides a distinct advantage for sustained high-rpm operation, ensuring consistent oil pressure and lubrication even under extreme cornering loads.

Regardless of the engine, adhering to recommended maintenance intervals and using high-quality lubricants and parts is crucial for maximizing longevity. Regular inspections and addressing issues promptly can prevent minor problems from escalating into major failures. Some recommended maintenance practices include:

Frequent Oil and Filter Changes

Inspecting and Replacing Worn Components

Using High-Quality Synthetic Oils

Monitoring Fluid Levels and Conditions

Addressing Leaks or Unusual Noises Promptly

The LS3's torque-rich nature and cost-effective pricing make it an excellent choice for street performance applications, where low-end grunt and affordability are priorities. Its robust bottom-end torque and simple bolt-on modifications make it a popular choice for street-legal thrills.

With its robust bottom-end torque and simple bolt-on modifications, the LS3 shines on the drag strip, propelling vehicles to impressive quarter-mile times. Its low-end power delivery and affordability make it a favorite among drag racers on a budget.

The LS3's compact dimensions and relatively straightforward wet sump oiling system have made it a popular choice for engine swap projects into lighter sports cars like the Mazda Miata. Its versatility and ease of installation have contributed to its widespread adoption in the engine swap community.

The LS7's high-revving character and prodigious top-end power make it the preferred choice for road course duty, where sustained high-rpm operation is common. Its ability to rev freely and produce maximum power at higher engine speeds gives it a distinct advantage on winding circuits.

For serious naturally aspirated builds targeting power levels over 600 hp, the LS7's higher airflow capabilities and free-revving nature give it a distinct advantage. Its larger valves, aggressive camshaft, and higher compression ratio allow it to extract maximum power without forced induction.

While the LS7's dry sump system adds complexity, it enables successful engine swaps into lightweight, high-performance vehicles where extreme cornering loads are expected. The dry sump system ensures consistent oil pressure and lubrication, even during high-g maneuvers, making it ideal for track-focused builds.

Price is a significant differentiating factor between these two powerhouses. A new LS3 crate engine from GM has an MSRP of $10,550, while the remaining stock of LS7 crate engines commands a premium price of around $16,600. This price gap narrows when building each engine to higher output levels, but the LS3 remains the more cost-effective option for a given power target.

Long-term ownership costs are fairly comparable, though the LS7's dry sump system adds some complexity and expense versus the LS3's conventional wet sump oiling. The table below summarizes the cost differences:

| Cost Factor | LS3 | LS7 |

|---|---|---|

| Crate Engine MSRP | $10,550 | $16,600 |

| Oiling System | Wet Sump (Simpler) | Dry Sump (More Complex) |

| Long-Term Maintenance | Comparable | Slightly Higher |

The LS3 and LS7 represent the pinnacle of GM's iconic small-block V8 design, offering enthusiasts a choice between torque-rich affordability and high-revving, uncompromising performance. While the LS7 reigns supreme in terms of outright power and top-end capabilities, the LS3 strikes a compelling balance of potency, reliability, and cost-effectiveness. Ultimately, the decision comes down to your specific needs and priorities, whether it's all-out track domination or street-legal thrills on a budget. Regardless of your choice, both engines exemplify GM's commitment to delivering legendary performance in a compact, lightweight package.

The LS7 has a higher compression ratio (11.0:1 vs 10.7:1 for LS3), larger valves, and a more aggressive camshaft profile for higher rpm operation. The LS3 has a wet sump oiling system, while the LS7 uses a dry sump system.

There is not a significant difference in fuel economy between the LS3 and LS7 when stock. The LS7 may have a slight advantage due to its higher compression ratio and more efficient combustion.

Yes, the LS3 can reliably handle forced induction with proper supporting modifications like upgraded fuel system, strengthened internal components, and tuning. Its thicker cylinder walls give it an advantage over the LS7 for boost.

Common issues with the LS7 include exhaust valve stem separation, oil pump failures, and the thin cylinder liners limiting boost potential.

The LS3's torque-rich nature and affordability make it a popular choice for drag racing applications where low-end grunt and cost-effectiveness are priorities.

The LS7's high-revving character and prodigious top-end power make it the preferred choice for road course duty, where sustained high-rpm operation is common.

A new LS3 crate engine has an MSRP of around $10,550, while the remaining stock of LS7 crate engines commands a premium price of around $16,600.

Yes, with the right supporting modifications like forced induction, upgraded fuel system, strengthened internal components, and tuning, both engines can safely generate well over 700 horsepower.

The LS7 has a higher redline of 6,800 rpm compared to the LS3's 6,600 rpm redline.

No, there are no significant weight differences between the two engines as they share the same aluminum block architecture and compact dimensions.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.