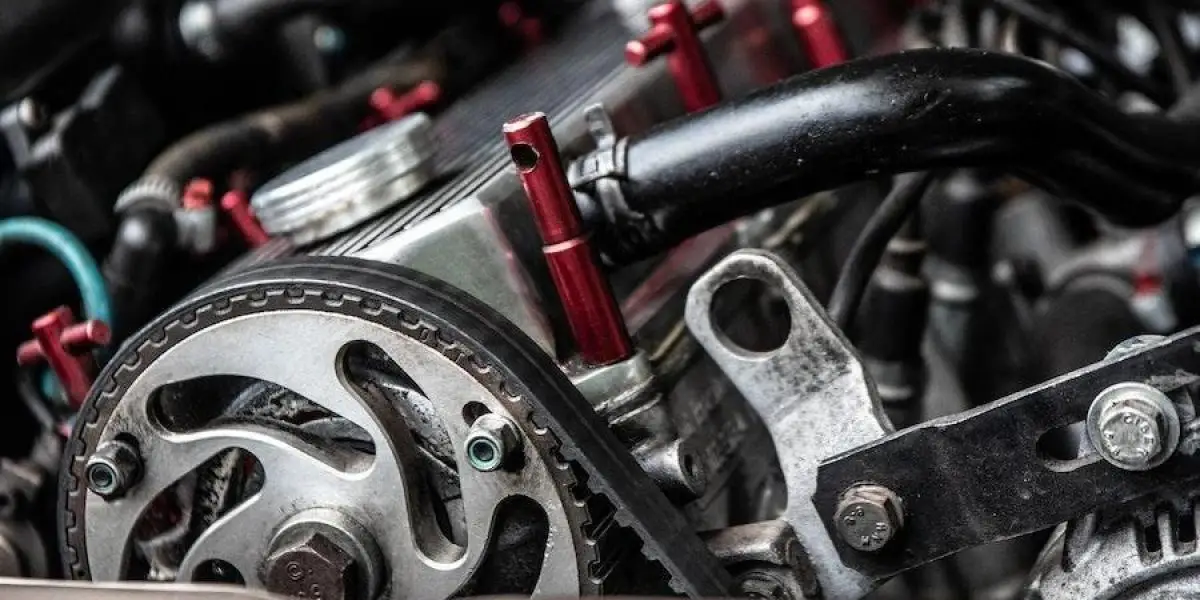

A timing belt, also known as a cambelt, is a critical component in an internal combustion engine that synchronizes the rotation of the crankshaft and camshaft(s). It plays a crucial role in ensuring proper valve timing and piston movement, which are essential for the efficient operation of an engine.

| Component | Function |

|---|---|

| Timing Belt | Synchronizes crankshaft and camshaft rotation |

| Crankshaft | Converts reciprocating motion of pistons into rotational motion |

| Camshaft(s) | Controls opening and closing of engine valves |

| Valves | Allow air/fuel mixture into cylinders and exhaust gases out |

| Pistons | Move up and down in cylinders to create combustion |

The timing belt is a toothed belt that runs between the crankshaft and camshaft(s), transferring the rotational motion from the crankshaft to the camshaft(s). This synchronization ensures that the engine's valves open and close at the precise moment when the pistons are in the correct position for optimal air/fuel mixture intake and exhaust expulsion.

If the timing belt breaks or becomes excessively worn, it can lead to severe engine damage. The consequences vary based on the engine type:

| Engine Type | Consequence of Timing Belt Failure |

|---|---|

| Interference Engine | Valves and pistons collide, potentially bending/breaking valves and damaging pistons and cylinder heads |

| Non-Interference Engine | No physical damage, but complete loss of engine power |

In interference engines, the valves and pistons occupy the same space within the cylinder at certain points during the engine cycle. If the timing belt fails, the valves and pistons can collide, causing catastrophic damage. In non-interference engines, the valves and pistons are designed to avoid collision, but a broken timing belt will prevent the engine from running due to improper valve timing.

There are three main types of timing belt constructions:

| Belt Type | Description | Advantages | Applications |

|---|---|---|---|

| Open-ended Timing Belts | High spring rate, excellent tooth shear strength, available in long rolls or cut lengths, often with steel tension members | Stiffness, high repeatability | Linear drives, industrial automation |

| Spliced and Welded Timing Belts | Heat-welded finger splices, sealed edge, smooth back, good strength | General-purpose, available in one-tooth increments | Conveying systems, welded profiles |

| Truly Endless (Extruded) Timing Belts | Extruded without welding, seamless loop, steel tension members, AT (trapezoidal) tooth profile | Strongest construction, enhanced tooth shear strength | Power transmission, industrial machinery |

Open-ended timing belts are suitable for linear drives that require stiffness and high repeatability, while spliced and welded timing belts are commonly used in general-purpose applications like conveying systems. Truly endless (extruded) timing belts are the strongest construction type, designed for power transmission applications that demand high loads and torque.

Timing belts are commonly made from materials like:

Neoprene

Polyurethane

Reinforced with fiberglass or aramid cords for added strength and durability

The tooth profile of a timing belt plays a crucial role in its performance and application. The three main tooth profiles are:

| Tooth Profile | Description | Advantages | Disadvantages |

|---|---|---|---|

| Trapezoidal | Flat-topped square ridges, common type | Effective force transmission for linear positioning and conveying | Faster wear at higher torques/speeds due to stress concentration |

| Curvilinear | Smoother, rounded tooth shape with deeper grooves | Reduces risk of tension loss (belt ratcheting), alleviates stress concentration at higher speeds/torques | Increased backlash (play between teeth and pulley grooves), less accurate positioning |

| Modified Curvilinear | Shallower tooth depths, steeper-sided teeth (flank angles) | Effective force transmission at higher speeds/torques, minimizes risk of ratcheting | - |

Trapezoidal belts are well-suited for linear positioning and conveying applications due to their effective force transmission capabilities, but they can experience faster wear at higher torques or speeds. Curvilinear belts help reduce the risk of tension loss and alleviate stress concentration on the teeth at higher speeds and torques, but they may have increased backlash, resulting in less accurate positioning. Modified curvilinear belts combine the strengths of both trapezoidal and curvilinear tooth shapes, making them suitable for demanding industrial applications.

Timely replacement of the timing belt is crucial for preventive maintenance and to avoid costly engine repairs. Most manufacturers recommend replacing the timing belt based on the following intervals:

Mileage-based: Every 60,000 to 90,000 miles (97,000 km to 127,000 km)

Time-based: Every 4 to 7 years, regardless of mileage driven

During a timing belt replacement service, several components are typically replaced in addition to the belt itself:

Tensioners

Idler pulleys

Water pump (if driven by the timing belt)

Replacing these components together can prevent future failures, as the labor required to access them is already being performed.

The cost of a timing belt replacement service can vary depending on the make and model of the vehicle, but it typically ranges from $400 to $1,000, including labor and parts. It is generally not recommended to attempt a timing belt replacement as a DIY project due to the complexity and potential for engine damage if done incorrectly.

Several warning signs may indicate that your vehicle's timing belt needs replacement:

Engine misfiring or rough idling

Squealing noise from the engine area

Loss of engine power

Engine won't turn over

If you notice any of these warning signs, it is crucial to have your vehicle inspected and the timing belt replaced promptly to avoid potential engine damage.

While timing belts are commonly used in many engines, some vehicles employ a timing chain instead. Timing chains are made of metal and are generally more durable than timing belts, capable of withstanding higher engine stresses. However, timing belts are quieter in operation and may be preferred in some applications.

| Component | Advantages | Disadvantages |

|---|---|---|

| Timing Belt | Quieter operation, may be preferred in some applications | Limited lifespan, requires periodic replacement |

| Timing Chain | More durable, can last for the entire engine lifetime in many cases | Produces more noise, especially as it ages and wears |

The choice between a timing belt or timing chain is typically made by the vehicle manufacturer based on factors such as engine design, performance requirements, and cost considerations.

The timing belt is a critical component in an internal combustion engine, responsible for synchronizing the rotation of the crankshaft and camshaft(s) to ensure proper valve timing and piston movement. Understanding its function, types, materials, and warning signs is essential for maintaining engine performance and longevity. Regular timing belt replacement, as recommended by the manufacturer, is crucial to prevent costly engine damage and ensure reliable vehicle operation.

A timing belt synchronizes the rotation of the crankshaft and camshaft(s) to ensure proper valve timing and piston movement. It is a critical component for the efficient operation of an internal combustion engine.

In interference engines, a broken timing belt can cause the valves and pistons to collide, resulting in catastrophic engine damage. In non-interference engines, it will lead to a complete loss of engine power.

The three main types are open-ended timing belts, spliced and welded timing belts, and truly endless (extruded) timing belts.

Timing belts are commonly made from materials like neoprene, polyurethane, and reinforced with fiberglass or aramid cords for added strength and durability.

The three main tooth profiles are trapezoidal, curvilinear, and modified curvilinear, each with its own advantages and disadvantages.

Most manufacturers recommend replacing the timing belt every 60,000 to 90,000 miles (97,000 km to 127,000 km) or every 4 to 7 years, whichever comes first.

In addition to the timing belt, tensioners, idler pulleys, and the water pump (if driven by the timing belt) are also commonly replaced.

Warning signs include engine misfiring, rough idling, squealing noise from the engine area, loss of engine power, and the engine not turning over.

Timing belts are made of rubber and have a limited lifespan, requiring periodic replacement, while timing chains are made of metal and are generally more durable, capable of lasting for the entire engine lifetime in many cases.

It is generally not recommended to attempt a timing belt replacement as a DIY project due to the complexity and potential for engine damage if done incorrectly.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.