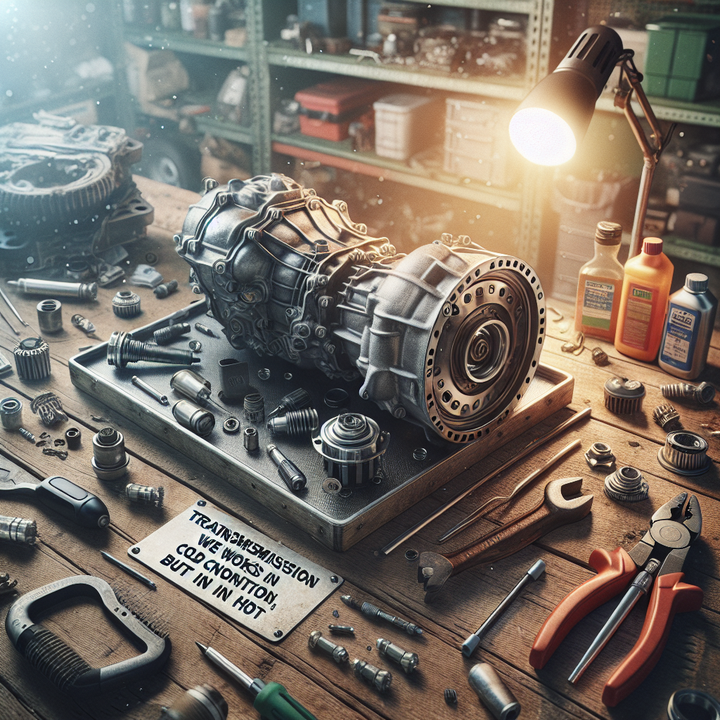

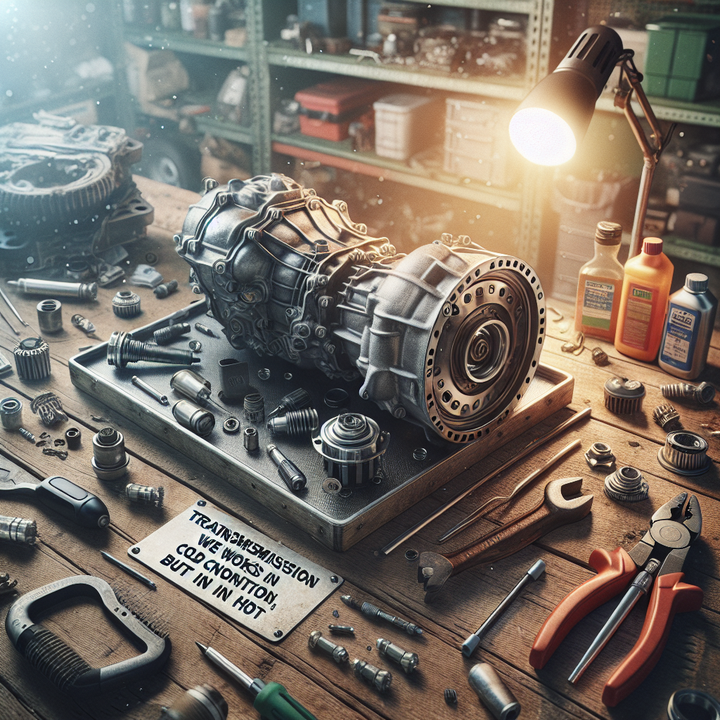

Transmission issues related to temperature variations are a common problem faced by many vehicle owners. Specifically, the scenario where the transmission works smoothly when the vehicle is cold but experiences problems when it gets hot is a recurring issue. This phenomenon can be attributed to various factors, including low or contaminated transmission fluid, overheating, and internal component wear or damage. Understanding the causes, symptoms, and potential solutions is crucial for addressing this problem effectively.

Before we dive into the nitty-gritty details, let me set the stage. Imagine you're cruising along on a sunny day, enjoying the open road, when suddenly your transmission starts acting up. Shifts become erratic, gears refuse to engage, and you're left wondering what in tarnation is going on. Frustrating, right? Well, fear not, my friends, because I'm here to shed some light on this puzzling predicament.

After years of diagnosing and fixing temperamental transmissions, I've narrowed down the most common causes behind this hot-and-cold behavior. Buckle up, because we're about to dive into the world of transmission troubleshooting.

| Cause | Description |

|---|---|

| Low or Contaminated Transmission Fluid | Just like your body needs blood to function properly, your transmission relies on fluid to lubricate, cool, and provide hydraulic pressure for smooth operation. When the fluid level is low or the fluid itself is old and contaminated, it can't do its job effectively, especially when the transmission gets hot. Imagine trying to run a marathon without proper hydration – you'd quickly run out of steam, right? Well, the same principle applies to your transmission. When the fluid can't keep up with the demands of heat and friction, it leads to slipping, delayed engagement, or even complete failure to shift gears. |

| Faulty Transmission Solenoids and Sensors | Your transmission is like a well-choreographed dance, with solenoids and sensors acting as the choreographers, telling the various components when and how to move. When these vital components fail, often due to heat-related issues, the transmission control module (the conductor of the dance) can't properly regulate shifting. Imagine trying to perform a complex dance routine without any guidance – it would be chaos! Similarly, when solenoids and sensors malfunction, you end up with erratic shifting, no upshifts, or an inability to engage gears when the transmission gets hot. |

| Internal Transmission Issues | Sometimes, the problem lies deep within the heart of the transmission itself. Worn clutch packs, damaged bands, or broken gears can all contribute to shifting issues when the unit gets hot and components expand due to thermal expansion. It's like having a well-oiled machine with a few loose screws – everything might work fine at first, but as the temperature rises and friction increases, those loose screws start causing havoc. The increased friction and lack of hydraulic pressure only exacerbate the internal wear, leading to a vicious cycle of transmission troubles. |

| Torque Converter Problems | While we're on the topic of internal components, let's not forget about the often-overlooked torque converter. This hydraulic coupling acts as the middleman, connecting the engine to the transmission and allowing power to be transferred smoothly. When the torque converter experiences issues like fluid leaks, bearing failures, or lockup clutch problems, it can prevent the transmission from transferring power properly when hot. It's like having a weak link in a chain – the whole system suffers as a result. |

Now that we've covered the potential culprits, it's time to roll up our sleeves and dive into the diagnostic process. As a mechanic, I follow a systematic approach to pinpoint the root cause of these hot transmission woes.

Check the fluid level and condition when the transmission is hot. If the fluid level is low or the fluid itself smells burnt, it's a clear indication of a leak or contamination issue. Think of it like checking the oil in your car – if it's low or looks like it's been through a war, you know something's not right. In the case of transmission fluid, low or contaminated fluid can't do its job properly, leading to all sorts of shifting shenanigans.

Connect a diagnostic scanner to the vehicle's computer system and check for any transmission fault codes. These codes can provide valuable clues, pointing us towards a specific solenoid, sensor, or internal issue that might be causing the hot transmission problems. It's like having a secret decoder ring that helps us decipher the transmission's language and understand what it's trying to tell us. With the right codes in hand, we can narrow down our search and focus our efforts on the most likely culprits.

Inspect the transmission cooler lines. These lines play a crucial role in keeping the transmission fluid at an optimal temperature, and any obstructions or leaks can lead to overheating issues. Imagine trying to cool down a hot engine with a garden hose that has kinks or holes – it's just not going to work very well. Similarly, if the transmission cooler lines are compromised, the fluid can't dissipate heat effectively, leading to all sorts of temperature-related transmission problems.

Perform a road test and listen carefully. During this test, we'll try to reproduce the shifting issues and pay close attention to any strange noises, slippage, or harsh engagements when the transmission gets hot. It's like being a detective, gathering clues and evidence to help us solve the case. Every little detail, from a subtle whine to a harsh clunk, can provide valuable insights into what's going on inside that temperamental transmission.

If all else fails, further diagnosis or transmission removal may be required. This could involve performing a pressure test to check the hydraulic system's integrity or, in some cases, even removing the transmission entirely to inspect the internal components. Think of it like a surgeon performing an exploratory surgery – sometimes, you just have to go in and take a closer look to find the source of the problem. While it's not a decision we take lightly, sometimes it's the only way to get to the bottom of those stubborn transmission issues.

Once we've identified the root cause of the hot transmission woes, it's time to roll up our sleeves and get to work on repairing the issue. But that's not all – we'll also discuss some preventative measures to help keep your transmission running smoothly for years to come.

| Repair | Description |

|---|---|

| Addressing Low or Contaminated Fluid | If the culprit turns out to be low or contaminated transmission fluid, the solution is relatively straightforward. We'll drain and replace the fluid and filter, ensuring that fresh, clean fluid is circulating through the system. Additionally, we'll inspect for any leaks or damaged seals and gaskets that might have caused the fluid loss or contamination in the first place. If necessary, we'll also flush the cooler lines to remove any lingering contaminants that could cause future issues. |

| Replacing Faulty Solenoids and Sensors | In the case of faulty solenoids or sensors, we'll diagnose the specific fault codes to identify the failed components. Once we've pinpointed the culprits, we'll replace the defective solenoids, sensors, or even the transmission control module if necessary. It's like giving your transmission a fresh set of eyes and ears – new solenoids and sensors will help ensure that the transmission can communicate effectively with the control module, allowing for smooth and precise shifting, even when the temperatures rise. |

| Overhauling the Transmission | If the issue lies within the depths of the transmission itself, a complete overhaul may be required. This involves disassembling the transmission, replacing worn bands, clutches, bearings, seals, and gaskets, and inspecting for any damaged gears that might need to be replaced. Think of it as a complete renovation project for your transmission – we'll strip it down to its bare bones, replace any worn or damaged components, and rebuild it from the ground up, ensuring that it's ready to tackle even the hottest of conditions. |

| Addressing Torque Converter Problems | In the case of torque converter issues, we may need to replace or rebuild the torque converter itself. This involves inspecting for fluid contamination and flushing the transmission to ensure that any debris or contaminants are removed from the system. It's like giving your transmission a fresh start – a new or rebuilt torque converter, combined with clean fluid, can help restore the smooth power transfer between the engine and transmission, even when things start to heat up. |

As for preventative maintenance, the key lies in following these practices:

Follow the manufacturer's recommended service intervals. This typically involves changing the transmission fluid and filter at regular intervals, as specified in your vehicle's owner's manual. Think of it like getting regular check-ups at the doctor – by staying on top of routine maintenance, you can catch potential issues early and address them before they become major problems.

Use the correct fluid type and ensure the fluid level is within the recommended range. Using the wrong fluid or running low on fluid can lead to all sorts of issues, including the dreaded hot transmission problems we've been discussing. It's like giving your transmission the proper nutrition it needs to function at its best. Just as you wouldn't feed a high-performance athlete a diet of junk food, you shouldn't skimp on the quality or quantity of transmission fluid your vehicle requires.

Avoid excessive towing, hauling, or high-stress driving whenever possible. Additionally, allow your transmission to warm up properly before subjecting it to high-load operation. This can help prevent premature wear and tear. Think of it like warming up before a workout – you wouldn't jump straight into intense exercise without stretching and preparing your muscles first, right? The same principle applies to your transmission. By taking it easy and allowing it to warm up gradually, you can help extend its lifespan and prevent those pesky hot transmission issues.

Address any cooling system issues that could lead to overheating. A well-functioning cooling system is essential for keeping your transmission at an optimal operating temperature, even under demanding conditions. Imagine trying to run a marathon in the middle of a desert without any water – it's just not going to end well. Similarly, if your cooling system isn't up to par, your transmission will struggle to dissipate heat effectively, leading to all sorts of temperature-related problems.

As with any repair or maintenance task, there are cost considerations to keep in mind when addressing hot transmission issues. The good news is that catching and addressing problems early can often prevent the need for more extensive (and expensive) repairs down the line.

| Repair | Typical Cost Range |

|---|---|

| Fluid Change and Filter Replacement | $100 - $300 |

| Solenoid/Sensor Replacement | $300 - $800 |

| Torque Converter Replacement | $500 - $1,200 |

| Transmission Overhaul (Parts and Labor) | $1,500 - $4,000 |

| Complete Transmission Replacement (Installed) | $1,800 - $5,000 |

On the lower end of the cost spectrum, a simple fluid change and filter replacement can typically run anywhere from $100 to $300, depending on your vehicle and the shop's labor rates. Replacing faulty solenoids or sensors can cost between $300 and $800, again depending on the specific components and labor involved. Think of these as the preventative maintenance and minor repair costs – a small investment now can potentially save you from much larger expenses down the road.

If the issue requires a torque converter replacement or a complete transmission overhaul, the costs can start to add up. A torque converter replacement can range from $500 to $1,200, while a full transmission overhaul (including parts and labor) can cost anywhere from $1,500 to $4,000, depending on the complexity of the job and the specific components that need to be replaced. These are the more significant repair costs, but they're often necessary to address deep-seated issues and restore your transmission to proper working condition.

In some cases, the most cost-effective solution may be to replace the transmission entirely. This is typically the most expensive option, with costs ranging from $1,800 to $5,000 for a new or rebuilt transmission, including installation and labor. While this may seem like a hefty investment, it's important to weigh the costs against the age and overall condition of your vehicle. Sometimes, a complete replacement is the most practical solution, especially if your transmission has seen better days and is nearing the end of its lifespan.

As we come to the end of our journey through the world of hot transmission woes, I hope you've gained a better understanding of the potential causes, diagnostic processes, and repair options available. Remember, addressing issues early and following proper maintenance practices can go a long way in preventing these temperature-related transmission problems from occurring in the first place.

So, the next time your transmission starts acting up when it's hot, don't panic! Take a deep breath, and remember that with the right knowledge and a little elbow grease, even the most temperamental transmissions can be tamed.

Stay cool, my friends, and keep those transmissions happy and healthy!

Manual transmissions can suffer from gear synchronizer issues and increased clutch wear in very hot weather. Frequent fluid changes and avoiding excessive clutch slippage can help mitigate these problems.

Using a block heater and transmission warmup period before driving can help prevent thick fluid and contraction issues. Installing a transmission oil pan heater is also an effective preventive measure.

Signs of transmission overheating include sluggish shifting, a burning smell, and transmission fluid that appears burnt or discolored. Addressing cooling system issues promptly is crucial.

No, using a thinner fluid than recommended can lead to inadequate lubrication and increased wear. Stick to the manufacturer's specified fluid type and viscosity for your vehicle.

Yes, it's advisable to let your car warm up for a few minutes before driving to allow the transmission fluid to circulate and reach optimal operating temperature.

Most manufacturers recommend changing the transmission fluid filter every 30,000 to 60,000 miles or as specified in your owner's manual.

A transmission flush is generally more thorough than a fluid change and can help remove sludge and contaminants from the system. However, it may not be necessary for every service interval.

Common signs of a failing torque converter include shuddering or vibrations during acceleration, slipping or poor engagement, and transmission overheating.

Driving with a transmission fluid leak is not recommended, as it can lead to further damage and potential transmission failure. It's best to have the leak diagnosed and repaired promptly.

If your transmission has sustained significant internal damage or wear, a rebuild or replacement may be necessary. Consult a professional mechanic for a proper diagnosis and cost estimate.

Sarah isn't your average gearhead. With a double major in Mechanical Engineering and Automotive Technology, she dived straight into the world of car repair. After 15 years of turning wrenches at dealerships and independent shops, Sarah joined MICDOT to share her expertise and passion for making cars run like new. Her in-depth knowledge and knack for explaining complex issues in simple terms make her a valuable asset to our team.